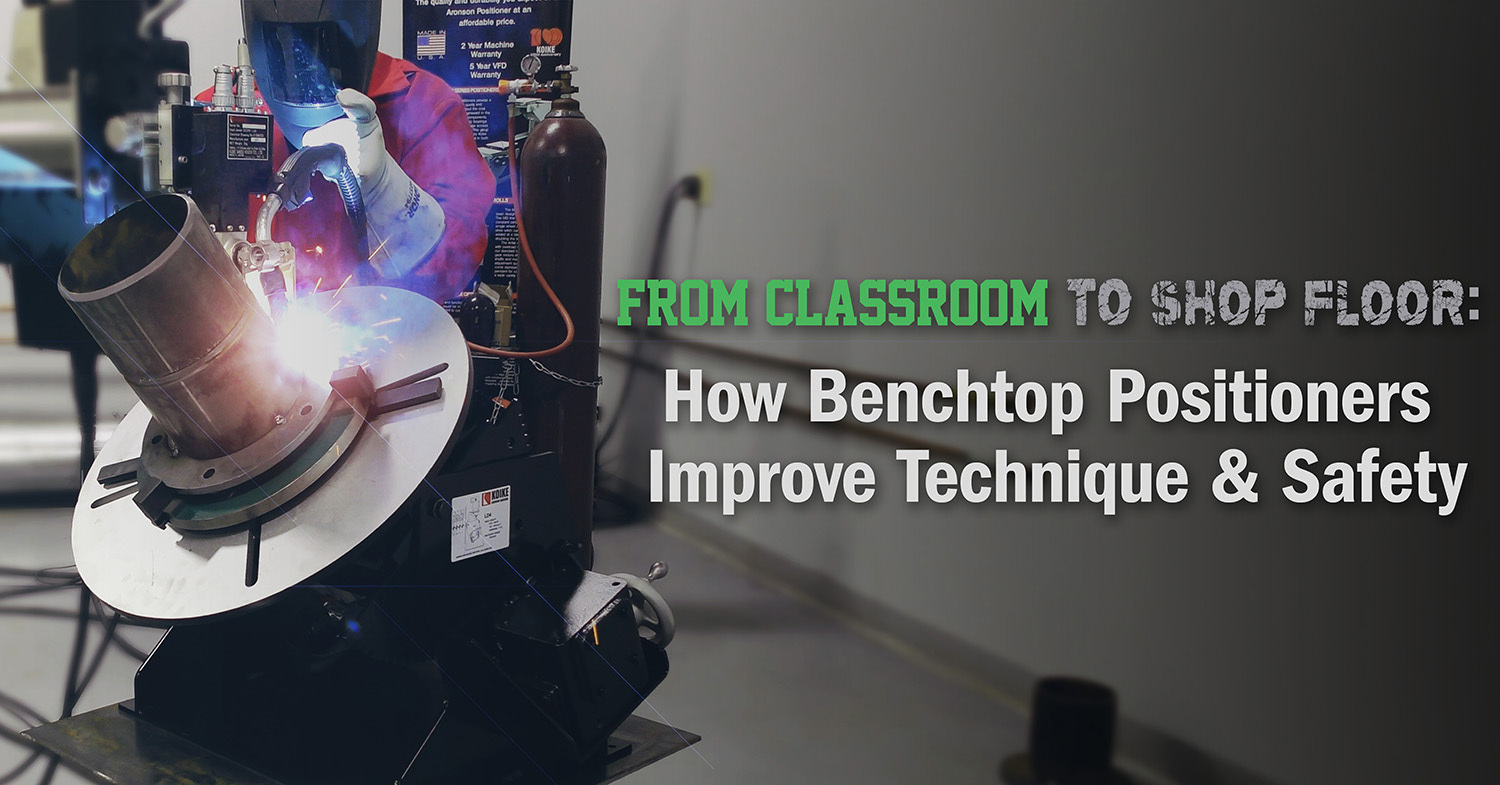

From Classroom to Shop Floor: How Benchtop Positioners Improve Technique & Safety

In the world of welding education, hands-on practice is everything. Whether you're training the next generation of pipefitters, fabricators, or shipbuilders, giving students the right tools to build muscle memory, understand weld positions, and reinforce safety habits is key. One piece of equipment that's making a big impact in vocational welding training is the benchtop positioner.

These compact but powerful devices are transforming welding classrooms by offering students real-world experiences in a controlled environment. When used with compatible accessories like chucks and torch stands, benchtop positioners become essential weld training equipment that bridges the gap between theory and practice.

Why Use a Benchtop Positioner in Vocational Welding Training?

Benchtop positioners simulate the dynamic welding conditions students will face in the field, allowing for safer, more consistent practice. Instead of constantly repositioning heavy parts by hand or relying on makeshift solutions, instructors can use these welding training equipment to rotate workpieces smoothly and safely into optimal welding positions.

Key benefits include:

- Improved weld quality through consistent positioning

- Reduced fatigue and better ergonomics for students

- Enhanced focus on technique rather than part handling

- Reduced risk of material handling Injuries

- Safe introduction to automation

|

Real-World Training Applications in the Classroom

Benchtop positioners shine when used to replicate actual welding tasks. Below are some ways instructors are using them to enrich the learning process:

- Welding Pipe to Flanges with a Chuck

Mounting a chuck onto the positioner allows students to securely hold round pipe or tube stock. They can then practice welding pipe to flanges — a critical skill in piping systems for plumbing, gas, and oil. This setup helps students control their weld puddle and maintain proper travel speed, especially useful for teaching MIG or TIG welding techniques.

- Cutting and Beveling Pipe Using a Torch Stand

Pairing the benchtop positioner with a torch stand allows instructors to safely teach pipe preparation. Students can rotate the pipe while a torch mounted on a stand performs a clean cut or bevel using oxy-fuel or plasma. This practice improves their understanding of cutting process and edge prep, an essential step in producing strong, defect-free welds.

- Teaching Fixed Automation Concepts

Benchtop positioners also offer an introduction to fixed automation. By integrating a mounted welding torch, instructors can simulate semi-automatic or automatic welding scenarios. Students gain insight into how consistent part rotation, stick-out and travel speeds affect weld penetration and appearance — key factors in automated welding systems used in manufacturing.

- Welding in Position: Training in 1G through 6G

A creative classroom project is to mount a small fabricated box on the benchtop table and challenge students to perform welds in all standard positions:

- 1G (Flat)

- 2G (Horizontal)

- 3G (Vertical)

- 4G (Overhead)

- 5G (Horizontal Pipe)

- 6G (Inclined Pipe)

By rotating the box or pipe fixture on the positioner, students can simulate welding in and out of position with precision, which is vital for certifications and real-world jobsite competence.

Better Practice Leads to Safer Welders

Using benchtop positioners in vocational welding training not only improves weld quality — it also boosts student safety. Welding accidents are often caused by poor posture, awkward angles, or fatigue from constantly repositioning heavy material. By making the part move, not the person, positioners reduce these risks.

Students also get to practice in a cleaner, more organized workspace, where they’re taught to work smarter — an important mindset that translates directly to safer jobsite behavior.

Designed for Beginners and Experts Alike

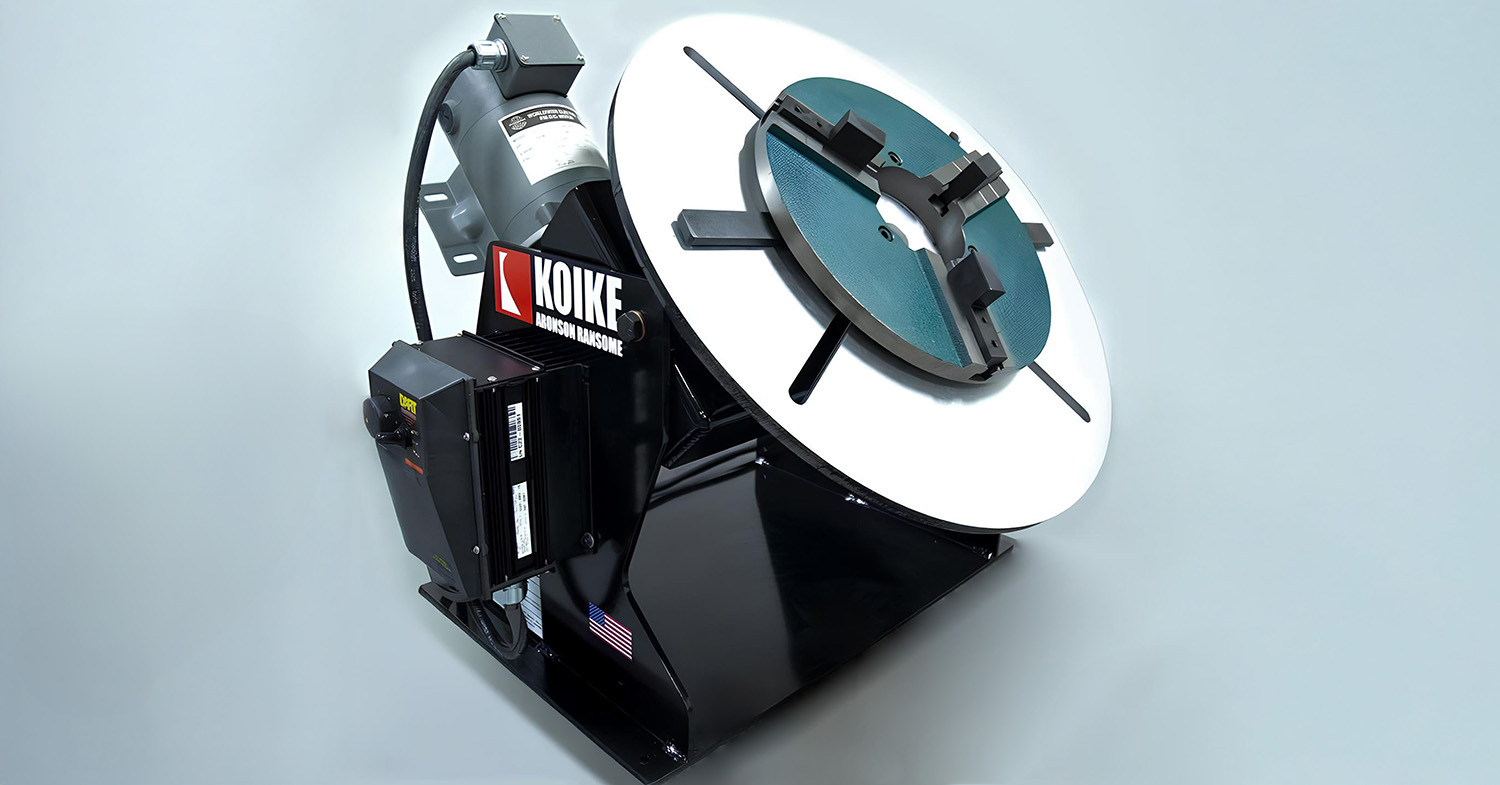

Whether you're teaching welding for beginners or preparing advanced students for industry certification, benchtop positioners offer scalable training support. They're a perfect match for today’s welding education requirements, helping schools and training programs meet performance standards while keeping classes engaging and hands-on.

The Future of Welding Education

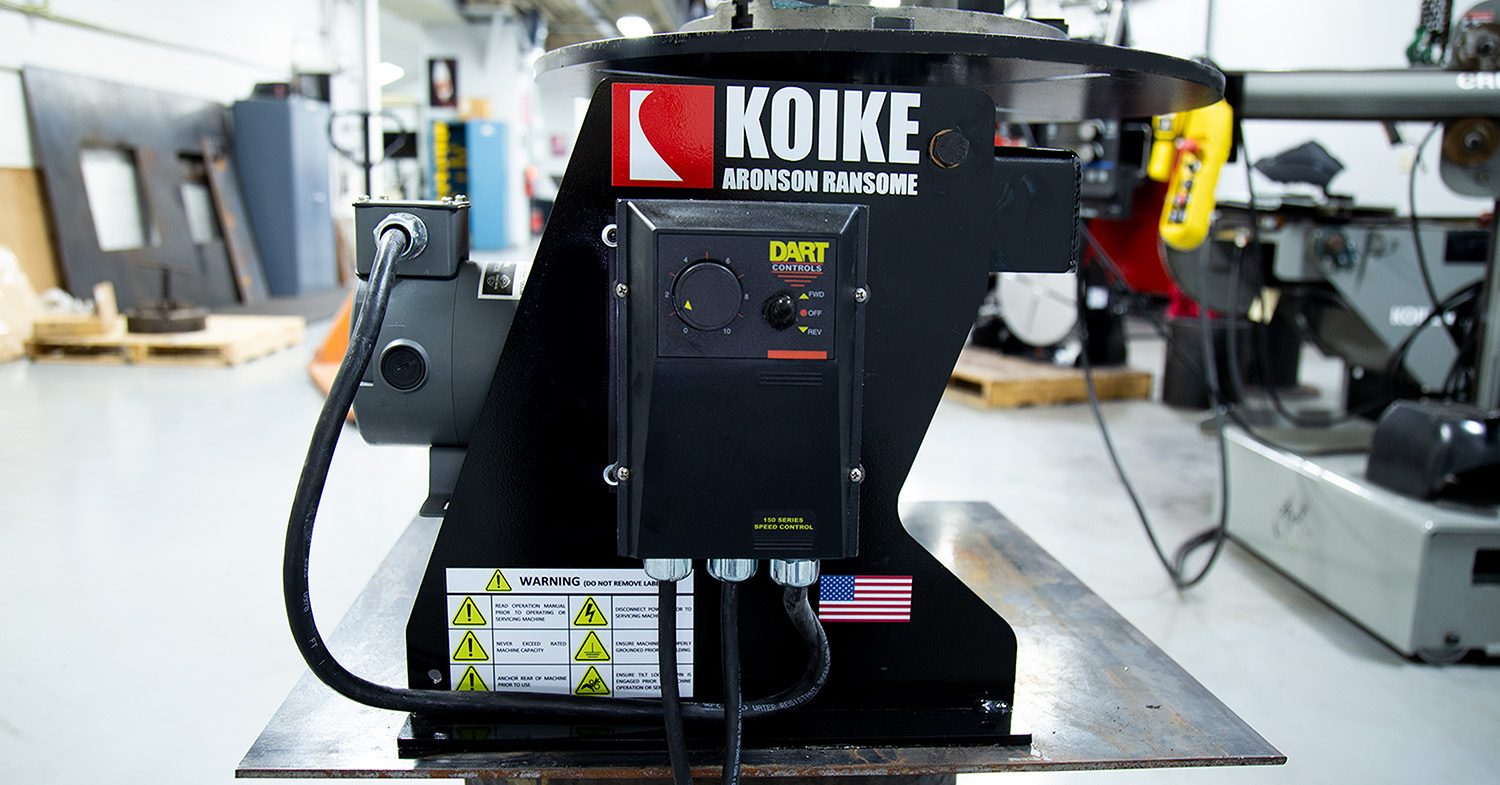

At Koike Aronson, we believe that great welders are built through great instruction — and the right tools. Our welding positioners engineered for durability, accuracy, and versatility in training and production environments. When paired with our cutting torches, chucks, and accessories, they form a powerful learning platform for the welders of tomorrow.

Ready to Elevate Your Welding Training?

Whether you're building a welding program from the ground up or upgrading your classroom equipment, Koike's Benchtop Positioners are built to deliver precision, safety, and real-world experience. Trusted by educators and professionals alike, these positioners are SIMPLY BETTER BUILT for lasting performance.

Explore our full lineup of Benchtop Positioners now:

Visit the Koike Bench Positioner Page