Shop Categories

-

Elevating

Adjustable Elevation for Diverse Workpiece Sizes and Configurations.

-

Fixed Height

Secure, Stationary Workpiece Positioning for Precision Fabrication and Manufacturing.

-

MD

Compact Single-Post Design with Elevation Capabilities for Cost-Effective Performance and Accessibility.

-

Specialty

Custom Solutions That Simplify Complex Welding Challenges

-

Koike Aronson, Inc

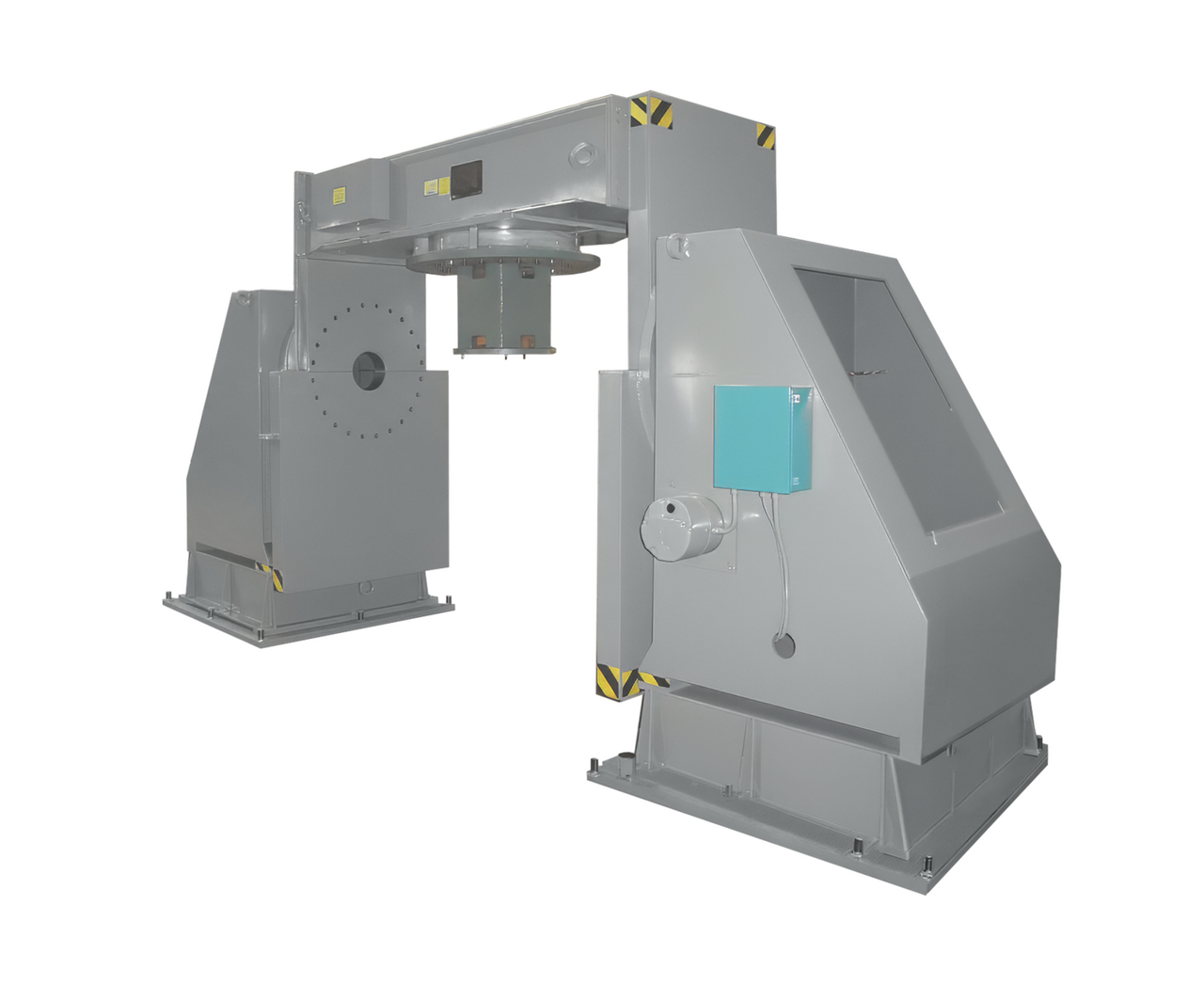

Skyhook

The HT Series Skyhook Positioner delivers 2-axis motion with continuous rotation and powered +/-180 degree tilt. Designed around your specific load and fixture requirements, each unit is custom engineered to handle complex, off-center applications...Learn More -

Koike Aronson, Inc

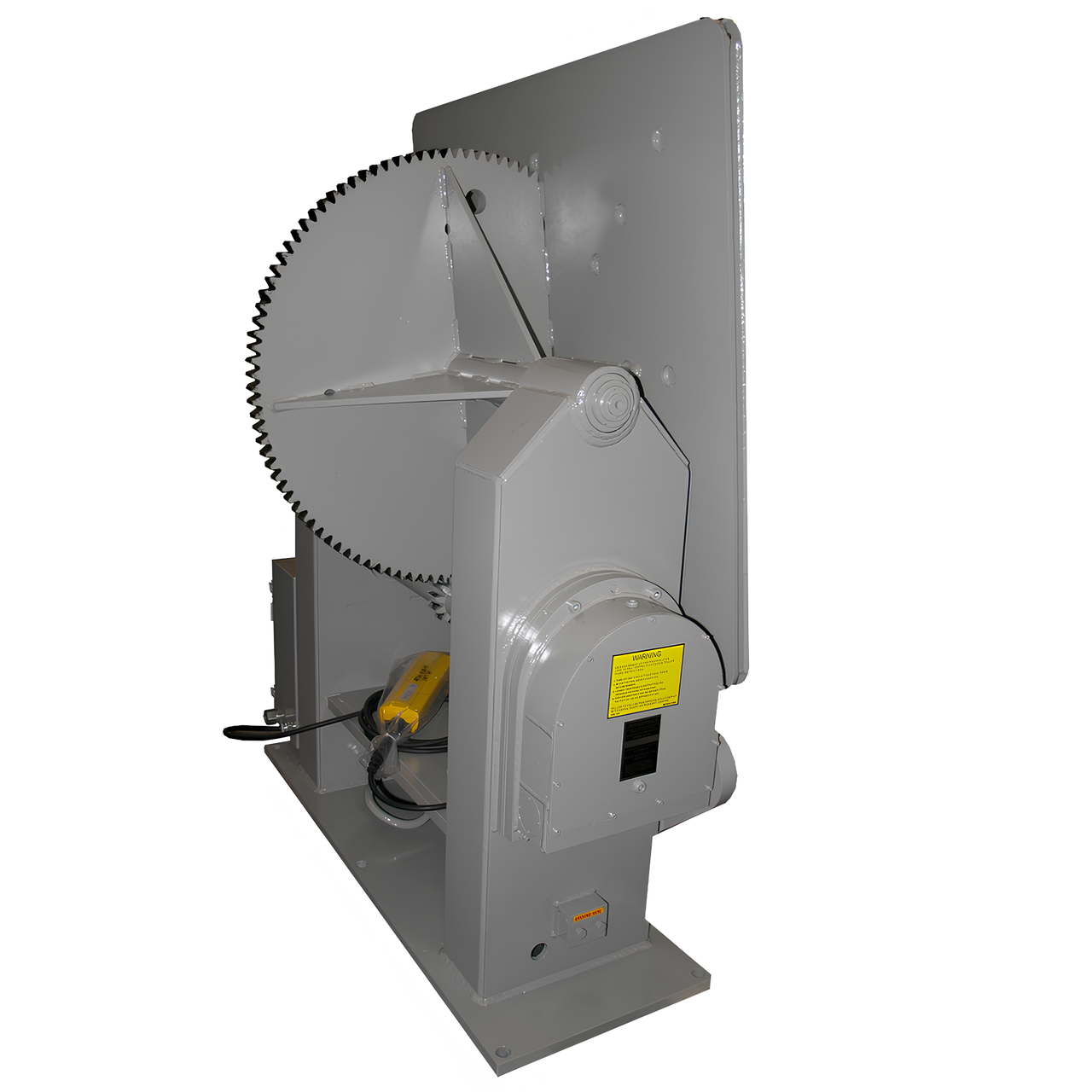

Drop Center

Introducing the HTSeries Drop Center (DCG) Gravity Positioners, a versatile line of gear driven welding positioners engineered for demanding industrial applications. The DCG Series provides two-axis motion with continuous rotation and +/-180 degree...Learn More -

Koike Aronson, Inc

Gear Elevating Head and Tailstocks

The Geared Elevation design enhances operator ergonomics and safety by integrating adjustable elevation capabilities into the Headstock and Tailstock positioners. This system retains all advantages of standard fixed-height models while allowing precise...Learn More -

Koike Aronson, Inc

MD-HTS-PE

Koike's MD series Power Elevating Head and Tailstock ━ premium features and long-lasting performance, all in a compact design. Designed to meet Koike's rigorous standards for top-tier performance, the MD-HTS-PE provides high-capacity, precision guidance...Learn More -

Koike Aronson, Inc

180 Degree Tilter | Compact Horizontal Axis Tilt For Down-Hand or Flat Welding Access

In many work environments, you may fine that a 180 Degree Tilter offers a swift alternative to the intricate setup often needed for head and tailstock positioners. Their 90 degree tilt from the horizontal position ensures convenient access for down-hand...Learn More -

Koike Aronson, Inc

Power Elevating Workpiece Elevation & Rotation System — Koike

The Powered Elevation design optimizes the use of readily available components, incorporating commercial ball screw jacks for reliable and high-duty cycle elevation operations, driven by a worm/wormgear arrangement. Two of these screw jacks are...Learn More -

Koike Aronson, Inc

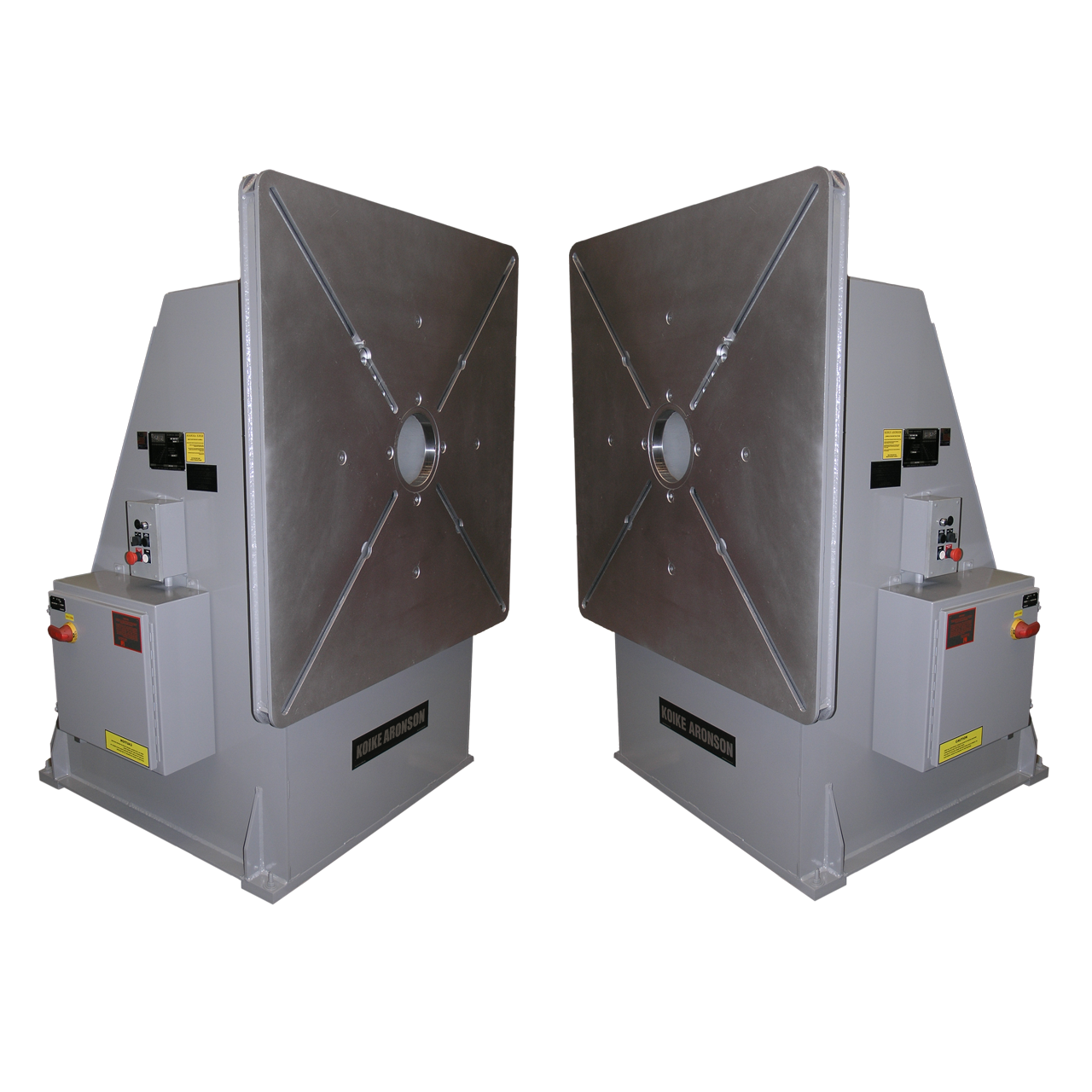

Fixed Height Stationary Workpiece Brace with Rotating Lathe Functionality

Fixed height Head and Tailstock positioners offer a wide range of capacities and customizable options, making them a practical solution for rotating long elliptical workpieces. When used together, these positioners occupy significantly less floor space...Learn More

The Role of Head & Tailstock Supports in Workpiece Positioning

Head and Tailstock supports are fundamental to secure, precise control of long or heavy workpieces during weldingand fabrication. By providing controlled rotation and ridged bracing , these units allow operators to position parts consistently, reduce manual handling, and achieve cleaner, more repeatable results in high production environments.

Why Head & Tailstock Supports Matter

- Consistent Rotation for Quality Work: By holding and rotating workpieces along their longitudinal axis, these supports ensure smooth, controlled motion that minimizes distortion and weld irregularities.

- Efficiency in Handling Large Assemblies: Head and tailstock positioners reduce the need for cranes, improving workflow while conserving shop floor space.

- Operator Safety and Productivity: Instead of manually repositioning heavy weldments, operators rely on powered, fixed supports to manage alignment.

Koike’s Adjustable Positioning Solutions

Koike offers a range of head and tailstock designs engineered for diverse shop requirements: elevating positioners accommodate varied workpiece sizes with flexible height control, while fixed height models deliver sturdy, space-saving rotation for repeat applications. Specialty configurations and power-elevating designs further expand versatility, ensuring shops can match the right system to their production demands.

Designed for welding and fabrication, Koike’s Simply Better Built head and tailstock systems provide advanced control, precise rotation, and dependable safety in every setup.

Ready to optimize your welding and fabrication setup? Get in touch with Koike Aronson to discuss the ideal Head and Tailstock solution for your operation.