Introducing the MasterGraph Katana MGK™, a state-of-the-art CNC oxy-fuel and plasma cutting machine designed to redefine precision, efficiency, and versatility in metal fabrication. Engineered with the same mechanical integrity as its predecessors, the MasterGraph EX2 and PlatePro XHD, the MasterGraph Katana MGK™ distinguishes itself with innovative advancements and superior control technology, updating the CNC interface of the MasterGraph platform to our cutting-edge Katana HMI controller.

A Master of Control : The Katana Controller Joins The MasterGraph

Standard Equipment :

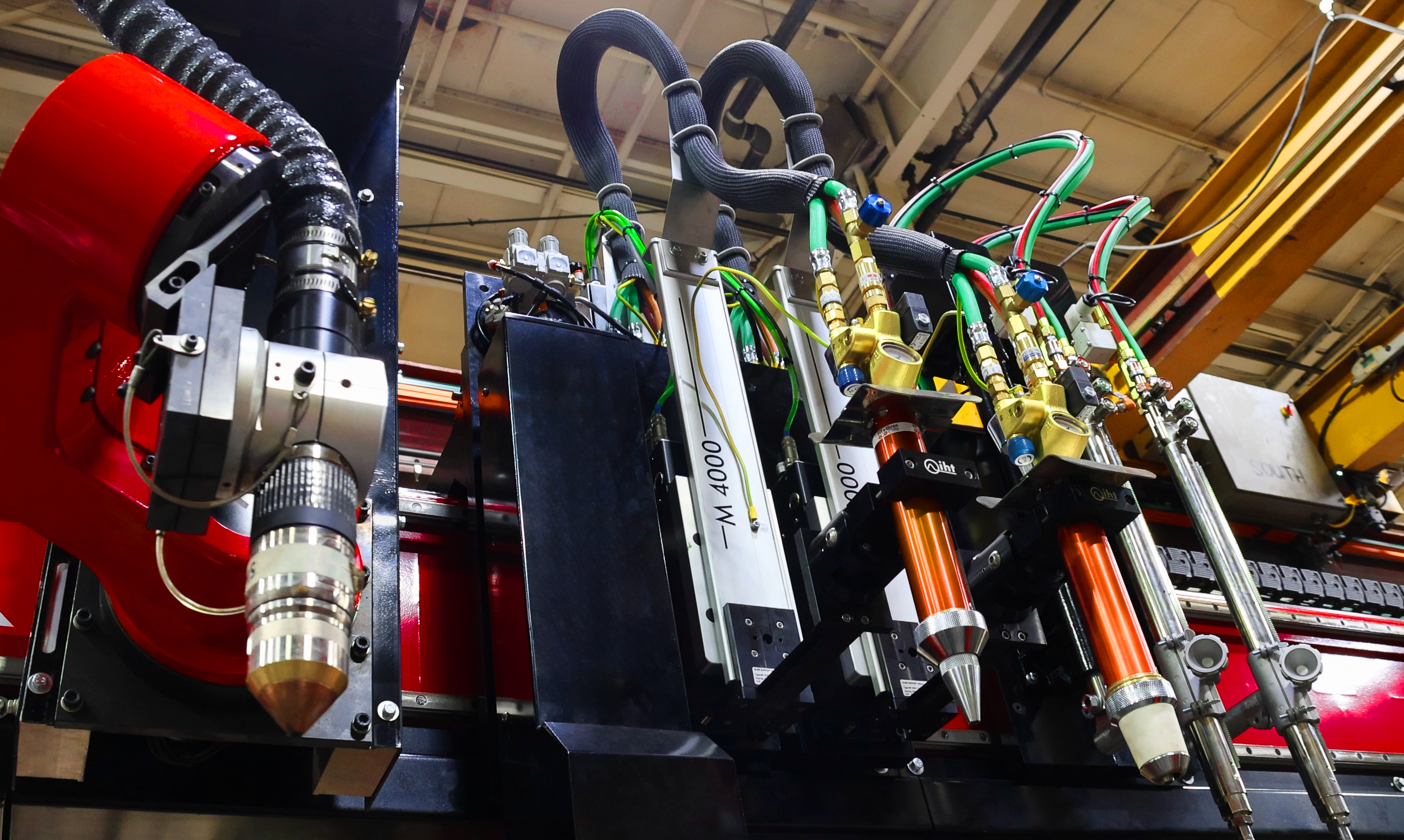

Pneumatic Slave Carriage Band Clamp has been engineered with air cylinders for auto-positioning and precise spacing of up to 8 oxy-fuel and plasma torches.

Newest additions of the optional 3D-X Full Contour Bevel Head, the IHT Automatic Process Control Torch Carriage, or Koike branded torch sets deliver incredibly precise bevel cuts with minimal dross.

Powerful Yaskawa Drives/Motors & Harmonic Drive Gearboxes deliver a large amount of torque to easily countersink holes with the optional 3D-X Full Contour Bevel Head.

The Transition to the Katana CNC Controller :

The MasterGraph platform, powered by the new Katana™ controller, broadens operational capabilities, allowing for more complex and precise cutting patterns that enhance efficiency and flexibility. The upgraded Human-Machine Interface (HMI), mounted on a dual swivel arm, ensures superior access and maneuverability, making it easier for users to make adjustments and interact with the system

Industrial Panel PC

KATANA CNC CONTROLLER WITH 21.5” TOUCH SCREEN

- An advanced operator control console featuring a 21.5" TFT display with a capacitive multi-touch screen, housed in a solid aluminum machined billet housing, running on Windows® 10 IoT Enterprise.

- Innovative software makes it easy for the operator to produce high quality parts from day one.

- Advanced interfaces for the plasma and torch height control systems provide the user with expert cutting process controls using preprogrammed cutting charts.

- Intelligent control algorithms, along with premium drive and motor technology, ensure the highest dynamic response and precision when cutting or marking.

- Remote Diagnostics and Servicing provides expert on-line support from our factory to yours.

Precision Movement on Every Axis :

Powerful AC Servo Motors

Robust Yaskawa Servo Motors boast 3 Kw,

1.34 HP X-Axis movement and 6 Kw, 8 HP

Y-Axis movement to deliver precise, smooth,

and accurate motion ensuring superior cut quality.

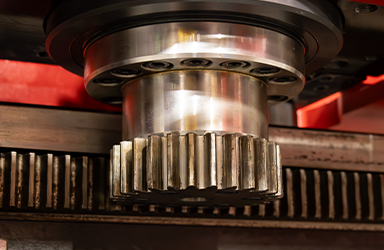

Large Diameter Drive Pinions

Large Diameter Pinions offer smooth and accurate motion, designed to achieve

1400 IPM rapid traverse

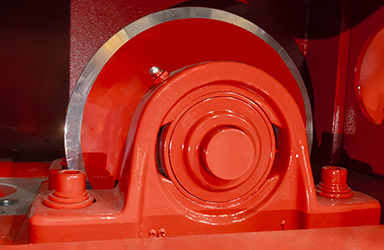

Large 8” Diameter Main Roller

The large heavy-duty main saddle rollers provide maximum stability for substantial loads.

Plasma System Options :

Hypertherm :

Hypertherm® XPR170® and XPR300®

XPR advances HyDefinition® cut quality by blending new technology with refined processes for next generation, X-Definition cutting on mild steel, stainless steel and aluminum using the same cutting

The XPR system increases cut speed, dramatically improves productivity and slashes operating costs. New ease-of-use features and engineered system optimization make XPR easier to run with minimal operator intervention and the same cutting consumables while also ensuring optimal performance and unmatched reliability.

KOIKE also boasts Hypertherm® True Hole® Technology certification. Bolt hole quality is delivered automatically without operator intervention allowing for precise cuts to exacting standards.

NEW!

Hypertherm® XPR460®

The Hypertherm® XPR460®, the newest addition to the Hypertherm® XPR plasma systems family, offers the most consistent cut quality, thicker cutting capabilities, and faster cutting speeds in its class, all while maintaining the same consoles (Torch Connect and Gas Connect including Core, CorePlus, VWI, and OptiMix), hardware (torch and receptacle, standard leads, sleeves), and accessories (rotational sleeve, nozzle retaining cap, and shield retaining cap).

The XPR460® delivers over 28% more output power (kW) than the HPR400XD®, allowing for mild steel piercing up to 2 1/2” and boasts significant reduction in operating costs by extending the life of consumables through Ramp Down Error Protection which prevents excessive arc stretch, shutting down system operations when consumable blowout is detected.

Ergonomic enhancements include a “double” negative lead with strain relief and a poka-yoked design, ensuring an installer-friendly setup. The work lead has also been extended to 35 meters (114.8 feet) to further ease installation.

Hypertherm® HPR400XD®

The Hypertherm® HPR System offer superior quality and consistency in cutting fine-feature parts, reducing the need for secondary operations. These systems boast long consumable life, quick consumable changes, dross-free edges, minimal angularity, and high reliability, maximizing productive “arc-on-time.”

Available in 130 to 800 amp options to meet diverse production demands.

Patented Hypertherm® PowerPierce® technology extends robust production pierce capability to 50 mm (2”) with 400 amps on mild steel and 75 mm (3”) with 800 amps on stainless steel and aluminum. Combined with a controlled motion process, the technology provides maximum stainless pierce capability up to 75 mm (3”) with 400 amps and 100 mm (4”) with 800 amps.

KJELLBERG :

KJELLBERG® SMART FOCUS 200®, 300®, 400®

For more than 60 years, Kjellberg has been one of the global market leaders supplying high-quality, high-precision plasma cutting systems and consumables. And now this German-engineered plasma cutting technology is available and supported in North America.

Kjellberg’s complete portfolio of innovative and adaptable cutting technology helps metal fabricators to make the most precise cuts with its standardized components, offering intelligent and simple-to-use systems for a high speed, low cosumption cutting solution.

Features Kjellberg’s Contour Cut Technology

Performs small contours, narrow webs and bolt holes with a diameter to material thickness ratio of 1:1, resulting in excellent quality parts cut with mild steel.

Contour Cut Speed allows the cutting of contours with a speed that is up to 50 % faster, producing precise cuts and higher cutting speeds. The unique cooling system up to the torch tip guarantees longest consumable life and reduces the gas consumption.

KJELLBERG® Q-Series®

The Q-Series® embodies exceptional performance, productivity, and cutting quality while prioritizing efficiency and cost-effectiveness with its high speeds and precision. Utilizing cutting-edge inverter technology, it minimizes its CO2 footprint, supporting climate protection efforts.

Offering plasma cutting up to 4 3/4 inches, marking, notching, graining, beveling, underwater plasma cutting, and precise contouring, it ensures exact results, including holes with a ratio of 0.75:1, showcasing its commitment to quality and innovation.

Plasma Equipment Options :

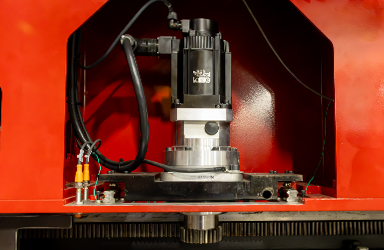

3D-X FULL CONTOUR BEVEL HEAD

Your favorite plasma bevel head from our PlateProXHD

makes its debut on the MasterGraph platform.

This head enables sophisticated 3D bevel cutting, facilitating precise angle cuts in multiple dimensions, performing A, V, X, Y, and K bevels.

The 3D-X design incorporates a helical rack and pinion lifter for fast, smooth, and precise motion, that delivers smaller corner loops and better hazard clearance at Y-axis 45 degrees.

Its advanced features ensure efficiency and precision, with one-touch homing and alignment capabilities, integrated torch breakaway, and concealed A/B axis motor and encoder cables.

MANUAL PLASMA BEVEL STATION

Allows for plasma beveling in the rail axis with non-contour

mechanical adjustment from +/- 0 to 45°.

KOIKE INTEGRATED SENSOR THC (TORCH HEIGHT CONTROL)

With a 12” (340.8 mm) lifter travel and a programmable lifter speed of 1,000 IPM, the Koike THC ensures swift and accurate adjustments during the cutting process.

Its adjustable stroke retract between cuts enhances operational efficiency, while dynamic positioning capabilities further optimize performance, enabling seamless adaptation to varying cutting conditions for consistent results.

OXY-Fuel Equipment Options :

KOIKE OXY-FUEL TORCH STATION

Model “G” motorized lifter, 6-inch (150 mm) stroke at 40 IPM.

All stations are controlled from the Operator console and can hold

up to 8 torches.

Includes three cutting tips and standard 500L Koike torch*, offering

plate cutting from 1/8” to 12” (3mm to 300mm) thick.

*Optional Manual Bevel Station Available for Koike 500L Torch

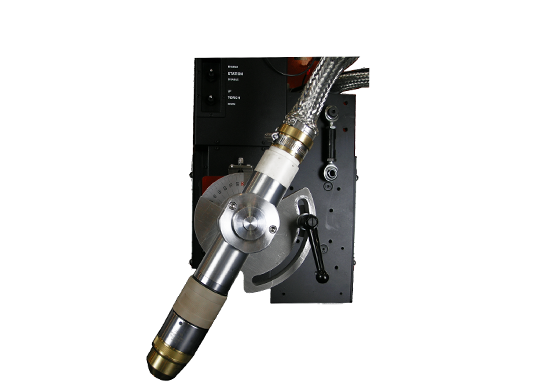

IHT AUTOMATIC PROCESS CONTROL (APC) SYSTEM

Delivers precise control of oxy-fuel operations, featuring the Cutting

Torch, Gas Control, Flame Ignition, Height Sensing, Lifter, and Bevel operations all in one package requiring only connections for oxygen

and fuel gas.

Additionally, all comprehensive database systems are implemented

directly into the CNC Console, automating the entire process from

ignition, preheating, piercing, and cutting, eliminating the need for

additional cutting control hardware.

Advanced features include flash back and slag detection to enhance

torch longevity, and allows close to edge cuts and kerfs with minimal

torch-to-torch distance.

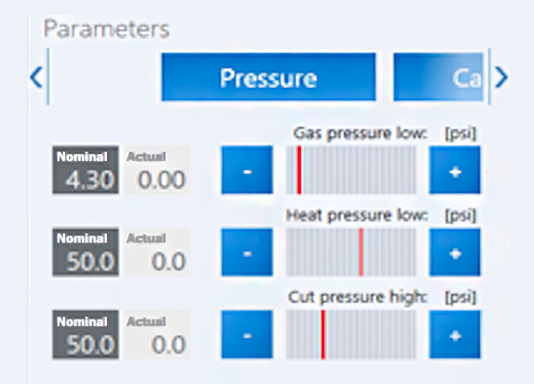

KOIKE AUTO-GAS SYSTEM FOR 500L TORCH :

Featuring Koike-designed Proportional Valves, this closed-loop system automates the setting and regulation of cutting oxygen, preheat oxygen,

and fuel gas pressures for oxy-fuel cutting while continuously monitoring

and maintaining precise gas flow and pressure.

Operators can select the tip size and plate thickness, and the system automatically adjusts the gas pressures from the Katana CNC.

HI-LO Oxy-Fuel Gas System with Auto Ease-On:

HI-LO system initiates faster preheating of plate, delivering superior cutting quality and precise piercing on thicker plate. Features auto ease-on pierce control for cut oxygen.