Shop Categories

-

Koike Aronson, Inc

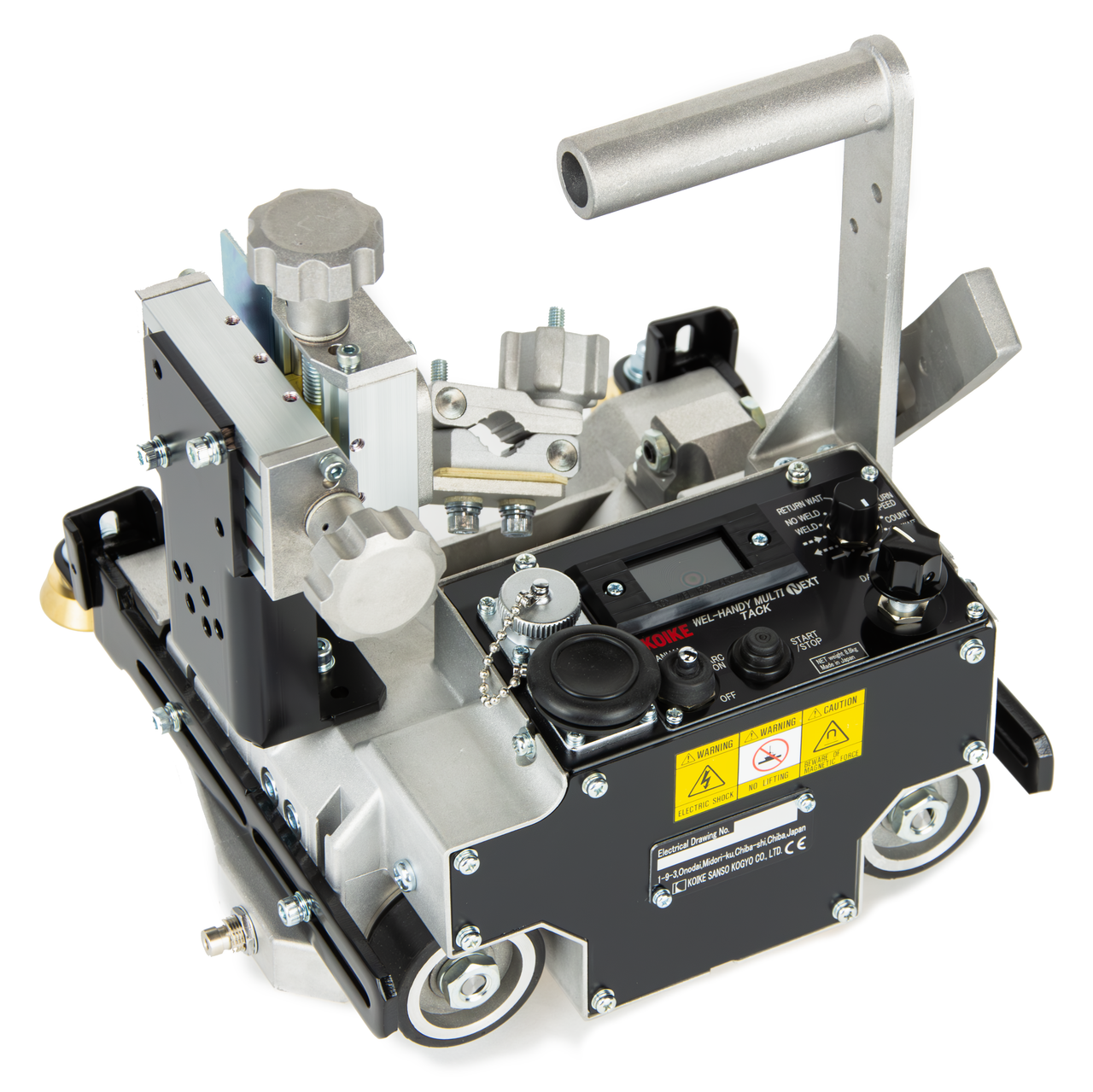

Wel-Handy Multi Next | Portable Trackless Fillet Welding Carriage

$4,987.50The Wel-Handy Multi Next redefines the industry standard of portable welding automation by merging lightweight design with rugged durability, all while eliminating the need of setting up cumbersome and time-consuming tracks or rails, perfect for fitting...Learn More

Learn More$4,987.50

Learn More$4,987.50- Continuous Fillet Welding

- Stitch Welding

- MIG / SAW

- 2 - 59 In Per Min

- Operable in Horizontal or Vertical Orientation

- 19.4 Lbs.

-

Koike Aronson, Inc

IK-72W Multi-II 3-in-1 Cutting & Welding Machine — Koike

$5,775.00One of three unique models within KOIKE's IK-72 Series, the IK-72W Multi-II offers a range of capabilities, including straight welding, plasma cutting, and oxy-fuel cutting. Experience consistent welds with ease, regardless of your skill level as the...Learn More

Learn More$5,775.00

Learn More$5,775.00- Continuous Fillet Welding

- Stitch Welding

- MIG / SAW

- 6 - 27.5 In. Per Min

- 3 Linkable Rail Options (Not Included)

- Operable in Vertical Orientation

-

Koike Aronson, Inc

IK-72 W1 3-in-1 Portable Cutting/Welding System — Koike

$4,620.00One of three unique models within KOIKE's IK-72 Series, the IK-72W1 presents a welding carriage of lightweight design with setup that demands minimal effort. For enhanced ergonomic comfort, a remote pendant facilitates the welder's operation from a more...Learn More

Learn More$4,620.00

Learn More$4,620.00- Continuous Fillet Welding

- MIG / SAW

- 6 - 27.5 In. Per Min

- 3 Linkable Rail Options (Not Included)

- Operable in Vertical Orientation

- 10 Lbs.

Portable Welding Machine

In metal fabrication and manufacturing, welding is a crucial process that joins materials to create various structures and products. It's best to buy these products from a reputable manufacturer such as Koike Aronson; we have over 100 years of experience and sell the best quality equipment. In our collection of portable welding machines, you'll find numerous options for trackless and track-guided welding. You can also buy optional equipment sets such as our plasma cutting or oxy-fuel cutting to get more use from your handheld welding machine.

To learn more about a tool, select one of the options. From here, you can review the quick specs, product description, and downloadable documents such as the manual. Contact us if you have questions about our portable welding machines or if you need assistance in selecting the right equipment for your needs.