Shop Categories

-

Chain Lift Manipulators

Chain-Driven Lift Delivers Pinpoint Welding Accuracy

-

Rack & Pinion Lift Systems

Our Aronson series column and boom welding manipulators consist of a linear rack and a rotating pinion to lift the welding head and wire vertically and provide precision horizontal motion while welding.

-

Cricket-I

Our compact, cost-effective welding manipulator features a robust body, powered lift, and optional floor track sections.

-

Cricket‑II Manipulator

Medium-Duty Ball Screw Manipulator with 500 lb Capacity and Powered Controls

-

Koike Aronson, Inc

Scarab Series

The Koike Aronson / Ransome Gear-Elevated Scarab Manipulator Series is built for safety and long life. All critical mechanisms are enclosed with welded, lifetime-lubricated gear cases, while concave wheels and roundways guide the lift and...Learn More -

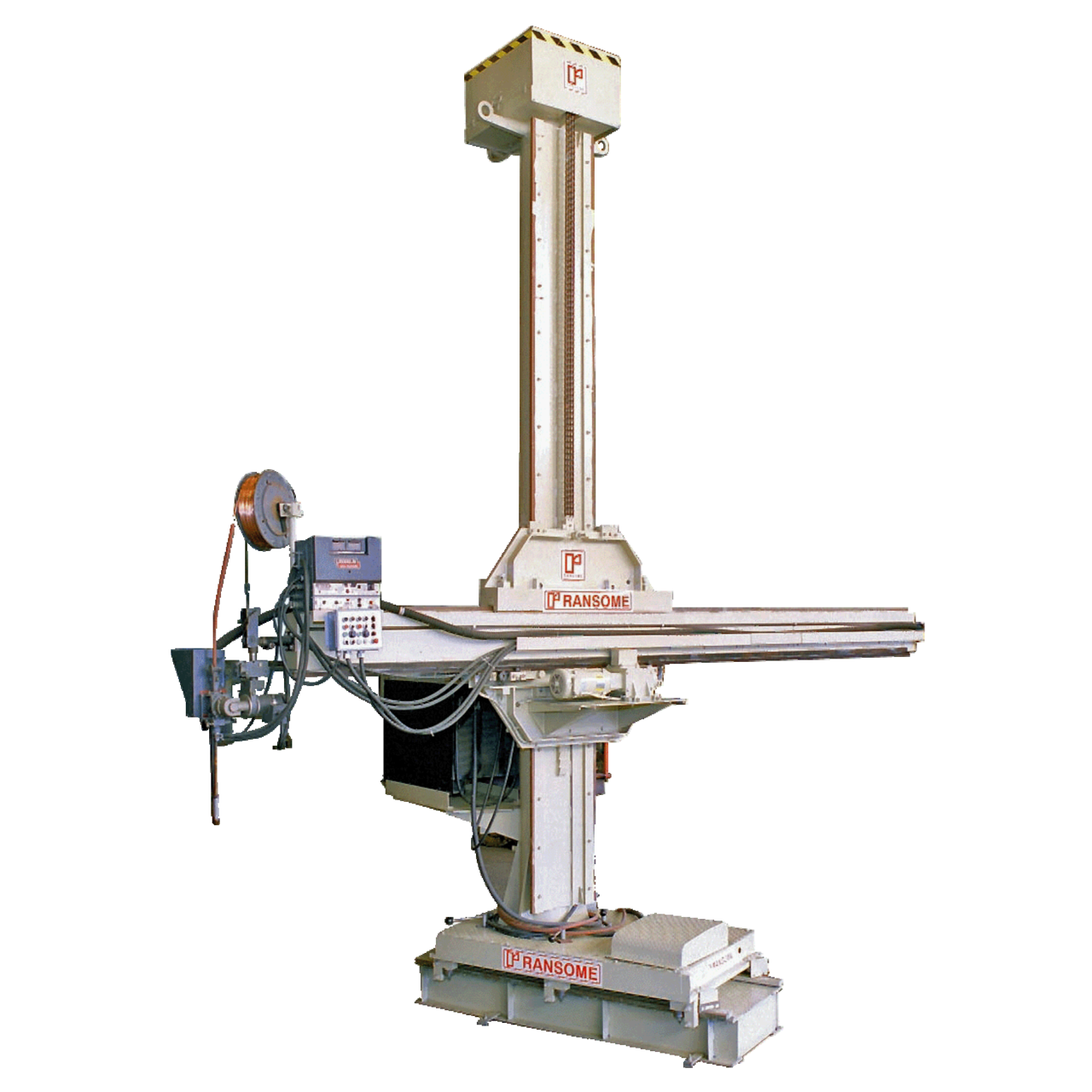

Koike Aronson, Inc

Locust Series

The Gear-elevated Locust Manipulator Series (Locust I and II) has been meticulously designed to ensure safety and deliver a trouble-free, extended lifespan. Key mechanisms are securely enclosed, load-bearing gear cases are expertly welded in place, and...Learn More -

Koike Aronson, Inc

Model 1212 Customizable High-Capacity Chain-Lift Welding Manipulator

The Model 1212, part of Koike Aronson's mid-range chain lift manipulator line, offers exceptional customization options tailored to specific applications, ranging from straightforward straight-line to intricate circumferential welding tasks. These...Learn More -

Koike Aronson, Inc

Model 99 High-Performance Customizable Chain-Lift Welding Manipulator

The Model 99, part of Koike Aronson's mid-range chain lift manipulator line, offers exceptional customization options tailored to specific applications, ranging from straightforward straight-line to intricate circumferential welding tasks. These...Learn More -

Koike Aronson, Inc

Model 66 Heavy-Duty Mid-Range Chain-Lift Welding Manipulator

The Model 66, part of Koike Aronson's mid-range chain lift manipulator line, offers exceptional customization options tailored to specific applications, ranging from straightforward straight-line to intricate circumferential welding tasks. These...Learn More -

Koike Aronson, Inc

Cricket II Medium-Duty Welding Manipulator — Koike

Introducing the Cricket-II Manipulator, a versatile welding solution designed to handle a wide range of applications with ease. This medium-duty ball screw manipulator boasts an impressive 500 lbs. load capacity, making it the standout choice for...Learn More -

Koike Aronson, Inc

Cricket-I | Compact & Robust Semi-Automatic Welding Manipulator

Ruggedly built, the Cricket-I provides the same reliability and robust performance found with all Koike machines, offering fabricators a variety of premium features with a small enough footprint to fit into any size shop. The Cricket-I provides a...Learn More

Koike Welding Manipulators: Precision, Power & Safety in Motion

The Ultimate Guide to Welding Manipulators

Welding manipulators are an essential complement to positioners, extending the reach, accuracy, and repeatability of welding processes. By moving the welding head precisely along multiple axes, manipulators enable fixed automation welding in applications that demand consistency and productivity.

Why Welding Manipulators Matter

Welding manipulators bring efficiency, consistency, and safety to industrial welding operations.

- Consistent, High-Quality Welds: Manipulators precisely move the welding head, ensuring uniform travel speed, angle, and distance. This reduces variation and weld defects, especially on long seams or repetitive jobs.

- Increased Productivity: Automated or semi-automated torch movement lets operators handle more work in less time. Combined with positioners and turning rolls, manipulators shorten cycle times and streamline workflows.

- Reduced Operator Strain: Instead of constantly adjusting themselves or moving large weldments, welders can let the manipulator position the torch. This improves ergonomics, reduces fatigue, and allows welders to focus on process quality.

- Safe Handling of Large Workpieces: In industries like pressure vessel fabrication, shipbuilding, or pipeline construction, weldments are massive and difficult to move manually. Manipulators remove the need for dangerous handling or awkward positioning.

- Versatile Applications: They’re used across sectors—tanks, structural steel, offshore components, energy infrastructure, wind towers—anywhere precision welding on large or repetitive projects is required.

- Integration with Positioners and Turning Rolls: When combined with other positioning equipment, manipulators create complete automated welding systems capable of handling virtually any geometry or size of workpiece.

Expanding Capabilities with Turning Rolls and Positioners

When used in combination with turning rolls and gear-driven positioners, welding manipulators provide a fully integrated solution for handling and welding even the largest and heaviest workpieces.

- Turning Rolls: These rotate cylindrical workpieces such as tanks, pressure vessels, and pipes, allowing for smooth, continuous welding around the circumference. Paired with a manipulator, they ensure precise torch travel and uniform weld beads.

- Gear-Driven Positioners: Ideal for angular and multi-axis parts, positioners tilt and rotate weldments into the optimal position. When paired with a manipulator, they allow welders to achieve complex welds on irregular geometries with consistency.

- Comprehensive Integration: Together, manipulators, turning rolls, and gear-driven positioners provide a complete system that can handle everything from rotating large-diameter vessels to welding intricate multi-joint assemblies.

Koike’s Range of Precision Welding Manipulators

Koike pushes boundaries with manipulator designs shaped by real feedback and daily shop challenges. Their line-up covers a range of needs for shops where high-quality results matter and flexibility is key.

1. The Cricket-I

Sized for small shops or tight spaces, this manipulator offers quick adjustments and user-friendly controls, so you can shift between tasks with ease.

2. The Scarab

Perfect for large-scale jobs, this solution is built for reliability and strength, supporting projects that need both muscle and finesse.

3. Customizable Chain-Lift Models

These allow for changes in height, rotation, and reach to match specific project needs so your shop can keep moving forward smoothly.

If you want that same level of innovation in other areas of your workflow, Koike’s CNC Cutting Machines deliver accuracy and freedom for advanced cutting requirements. Each manipulator in Koike’s line is crafted with everyday work in mind, giving you simple controls and steady support.

If you want that same level of innovation in other areas of your workflow, Koike’s CNC Cutting Machines deliver accuracy and freedom for advanced cutting requirements. Each manipulator in Koike’s line is crafted with everyday work in mind, giving you simple controls and steady support.

How to Choose the Right Precision Welding Manipulator

When choosing a manipulator, start with your team’s needs:

1. Precision and Control

For projects that demand accuracy, look for options with advanced controls and careful adjustment features.

2. Capacity

Match your tool to the weight and size you handle most. Compact manipulators like the Cricket-I work well for lighter tasks, while the Scarab is set for bigger jobs.

3. Safety Features

Look for models with remote use, solid bases, and simple adjustments to support a safe workday.

4. Adaptability

Prepare for future jobs. Chain-lift models help you move between different tasks without downtime. If you need portable solutions for on-site welding or flexible shop setups, Koike’s Portable Automation options provide even more ways to keep your work moving efficiently.

5. Value Over Time

Look beyond upfront cost. Practical, long-lasting tools keep your workflow steady and help you avoid unnecessary interruptions. With thoughtful planning, you’ll select a manipulator that fits your plans now and in the years ahead.

Making the Most of Your Welding Investment

Today’s manipulators help your team get results they can trust and enjoy smoother days at work. Koike’s range from compact to heavy-duty and flexible models meets real needs without making things complicated. The right welding manipulator makes work feel more straightforward and helps you accomplish more.

Ready to upgrade your welding setup? Contact Koike Aronson today to discuss your project requirements and find the perfect manipulator for your shop.