-

Koike Aronson, Inc

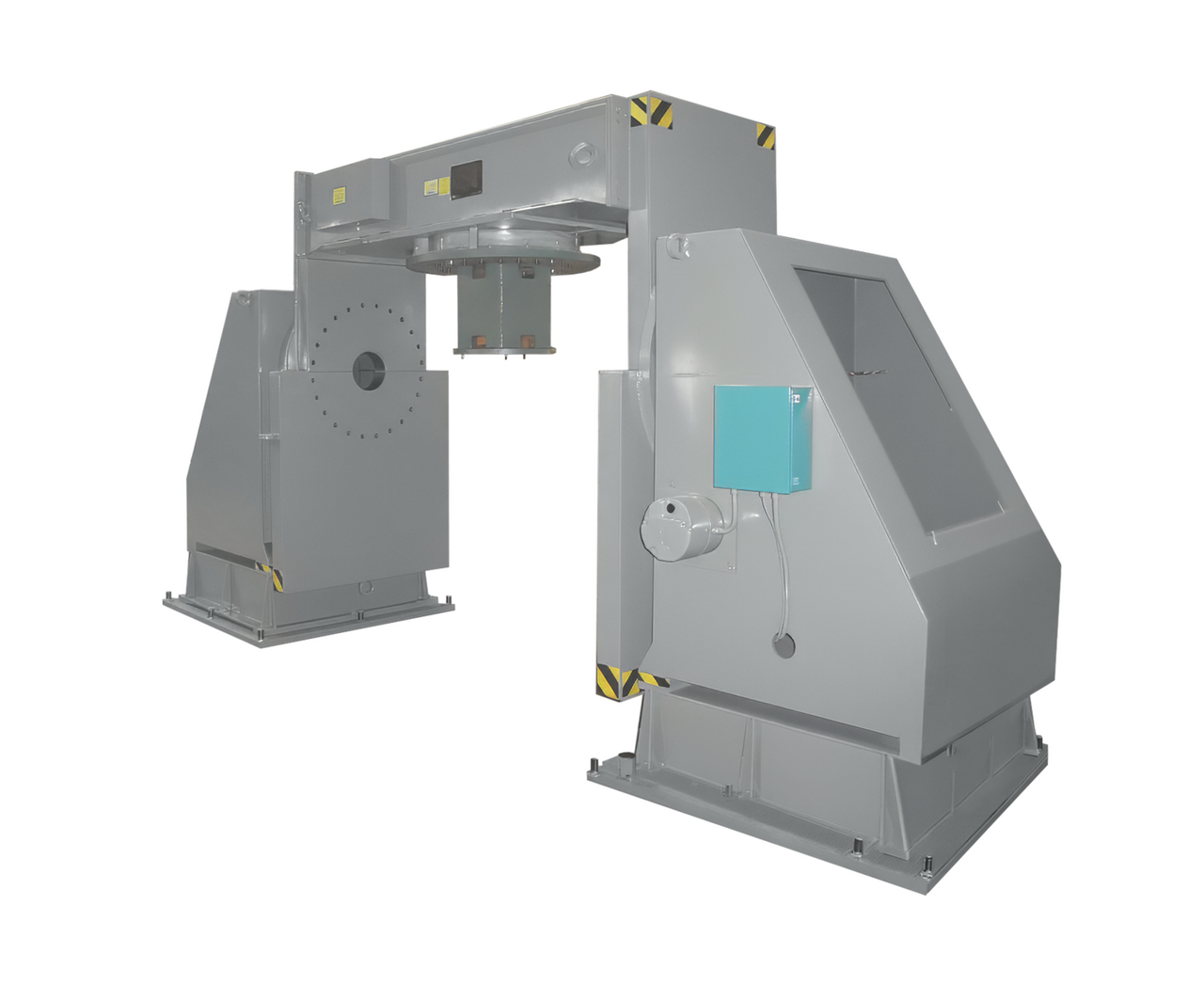

Skyhook

The HT Series Skyhook Positioner delivers 2-axis motion with continuous rotation and powered +/-180 degree tilt. Designed around your specific load and fixture requirements, each unit is custom engineered to handle complex, off-center applications...Learn More -

Koike Aronson, Inc

Drop Center

Introducing the HTSeries Drop Center (DCG) Gravity Positioners, a versatile line of gear driven welding positioners engineered for demanding industrial applications. The DCG Series provides two-axis motion with continuous rotation and +/-180 degree...Learn More -

Koike Aronson, Inc

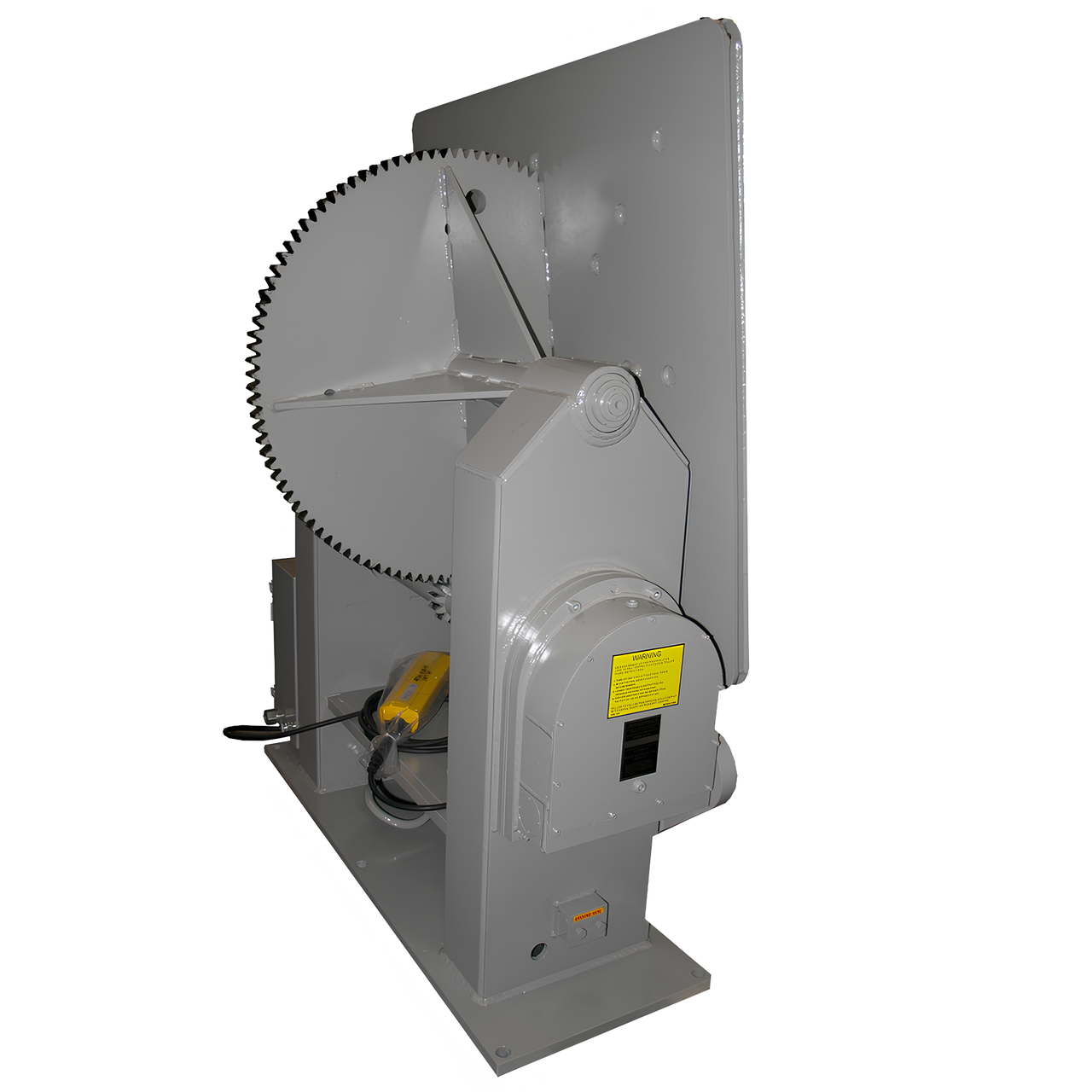

180 Degree Tilter | Compact Horizontal Axis Tilt For Down-Hand or Flat Welding Access

In many work environments, you may fine that a 180 Degree Tilter offers a swift alternative to the intricate setup often needed for head and tailstock positioners. Their 90 degree tilt from the horizontal position ensures convenient access for down-hand...Learn More

Specialty Head & Tailstock Systems for Specialized Welding

Optimized Part Positioning: For Specialty Head & Tailstock for Advanced Welding Applications

Imagine a fabrication shop is building a heavy steel frame. The welder needs access to the end joints, but the frame is too short for a head & tailstock and too awkward to flip by hand. The only option is a crane lift—slow, risky, and hard on both the crew and the part.

With the 180° Tilt Positioner, the problem disappears. The frame locks securely in place. A single tilt exposes the end for welding, another flip gives access to the opposite side. No crane, no wasted time, no back strain. Just controlled movement, perfect positioning, and a smaller footprint that keeps the shop floor clear.

The job gets done faster, safer, and with the precision Koike is known for.

Tailored Positioning for Non-Standard Welding Tasks

Welding projects rarely follow a "one-size-fits-all" approach. This is particularly true for industries requiring custom or asymmetrical components, where conventional welding positioners can fall short.

Applications

- End Access: Weld, or inspect part ends with zero crane handling.

- Side-to-Side Flipping: Safely reposition workpieces for opposite-side welds or finishing.

- Head & Tailstock Alternative: Ideal for parts that are too short, asymmetrical, or irregularly shaped.

- Compact Fabrication Cells: Fits where floor space is tight—delivering maximum efficiency.

- General Fabrication: Perfect for structural frames, engine blocks rebuilds, beams, box sections, and OEM assemblies.

If you want to explore more about these solutions, you can learn about their full range of Positioning and Welding tools.

Increasing Welding Efficiency

Time efficiency also plays a vital role in specialized welding. The compact custom fixtures found in specialty head & tailstock positioners, such as those offered by Koike, streamline the process. These fixtures minimize setup complexities, enabling welders to secure parts easily regardless of their unique geometry.

When parts are held firmly in place and align properly, the risk of rework decreases. Welders can execute jobs more quickly without compromising the final outcome. And these systems allow operators to maintain ergonomic working conditions, which enhances productivity further by reducing fatigue over longer welding sessions.

Benefits of Specialty Welding Positioners

Koike's commitment to providing compact and customizable fixtures ensures their positioners can adapt to diverse manufacturing environments. Whether you're rotating lengthy workpieces or handling complex assemblies, these systems can be tailored to complement the task at hand. For teams aiming to streamline fabrication further, complementary tools like Koike's CNC cutting machines help set the stage for accuracy before welding even begins.

Investing in Cutting-Edge Welding Solutions

The use of highly specialized equipment like specialty head & tailstock systems reflects an investment in quality and safety. For manufacturers, these tools represent a shift toward adopting smarter solutions that promote both quality and efficiency. By integrating systems like Koike's into their workflows, organizations can handle increasingly complex weld requirements while maintaining high standards.

Ultimately, these systems also contribute to better outcomes for the end product. Seamless, uniform welds reduce the likelihood of defects, setting a strong standard for finished components.

Solutions Are Available

Specialty head & tailstock systems have transformed the way non-standard parts are welded.

Ready to simplify complex welds? Discover how Koike’s specialty systems can elevate your next project.