The Powered Elevation design optimizes the use of readily available components, incorporating commercial ball screw jacks for reliable and high-duty cycle elevation operations, driven by a worm/wormgear arrangement. Two of these screw jacks are coupled together and driven by a common motor for redundancy, eliminating the need for belts, chains, or transfer gears.

Guidance is facilitated by large-diameter cam follower bearings on flat guide-ways, adjustable for wear, ensuring stability on all sides of the two supporting columns that bear the cantilevered load.

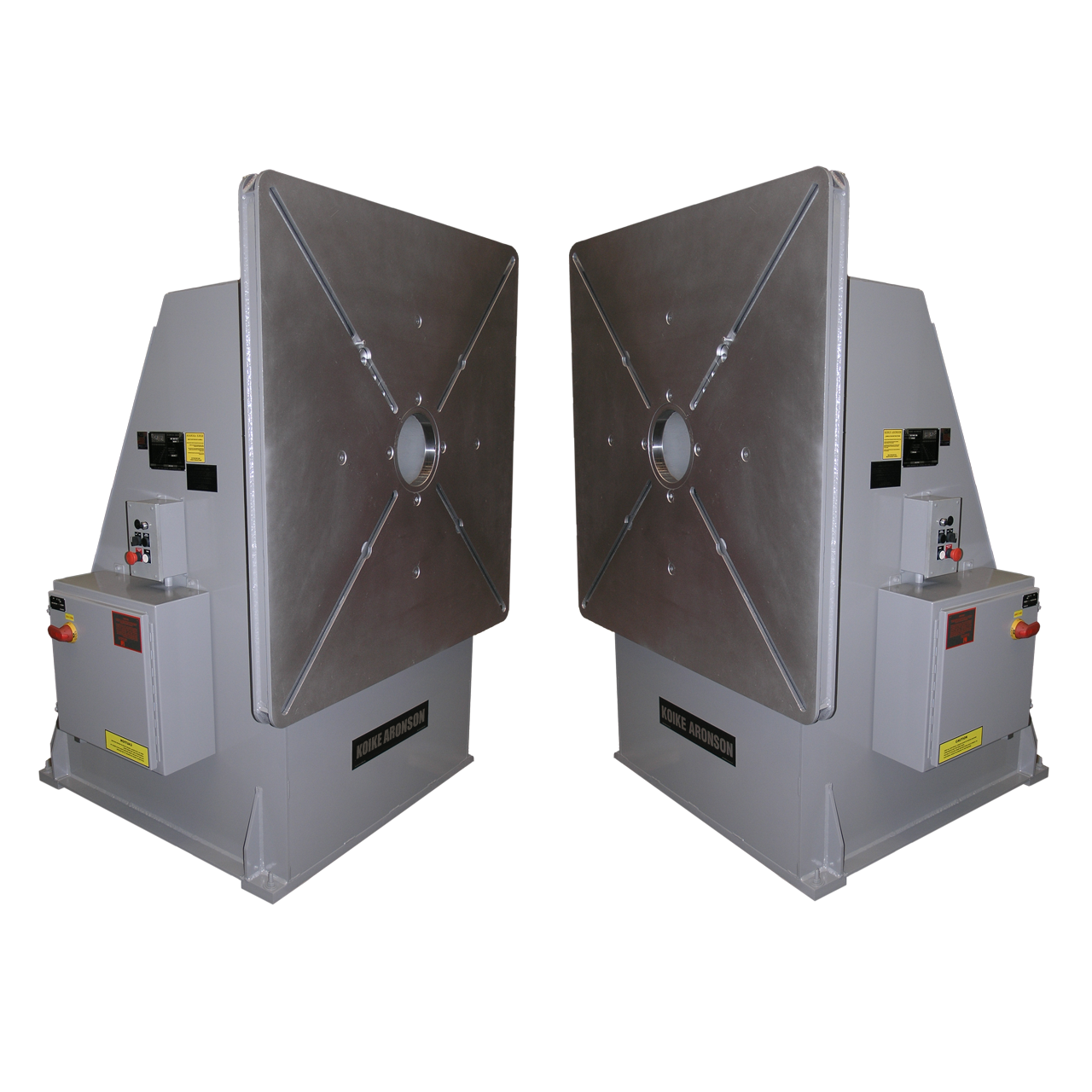

In Koike Aronson Ransome systems, the Headstock and Tailstock axes are electronically synchronized to prevent workpiece/fixture skewing. Both axes are powered by encoded motors controlled by drives with internal PLC capabilities. Encoder information from both axes is transmitted to the Tailstock drive, which receives closed-loop position data from the Tailstock encoder, tracking the reference signal from the Headstock encoder. The Headstock drive and motor respond to operator control pendant commands or, optionally, a supervisory programmable control system. As the Headstock moves, the Tailstock seamlessly follows step-by-step, guided by encoder feedback. Any detected errors, either internally or externally, prompt the system to halt immediately to prevent workpiece/fixture skewing.

Features and Standard Equipment

- Low Efficiency Gear-Boxes:

Maintains smooth and controlled movements during operation.

- Reliable Ball Screw Jacks:

Ensures high-duty cycle reliability.

- Machined Tables:

Equipped with precision machined tables for stable workpiece support.

- Hand Control Pendants:

Low-voltage hand control pendants for precise operation.

- Variable Speed Drives:

Equipped with 50:1 variable speed drives for optimal control.

- Elevation Jack Boots:

Protects screw components from debris to ensure extended lifespan.