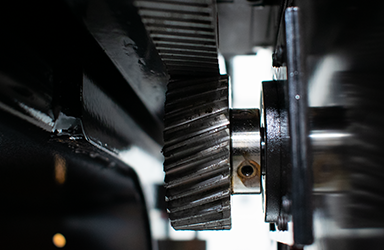

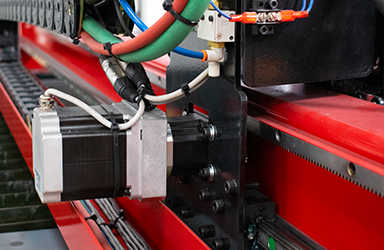

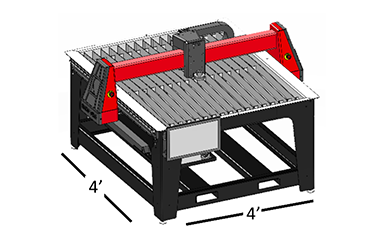

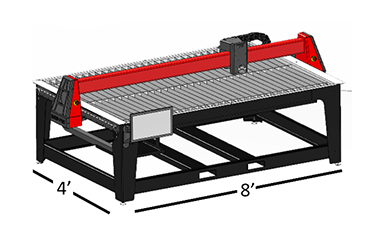

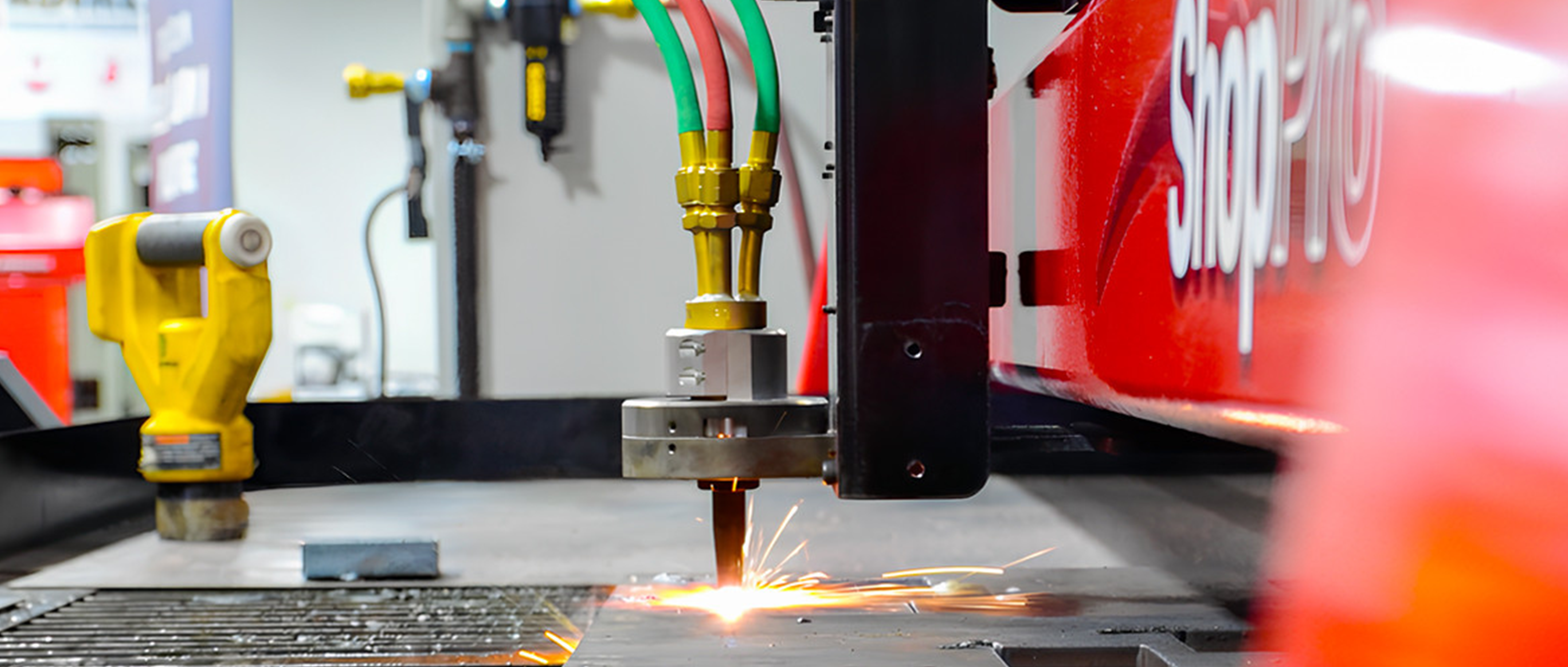

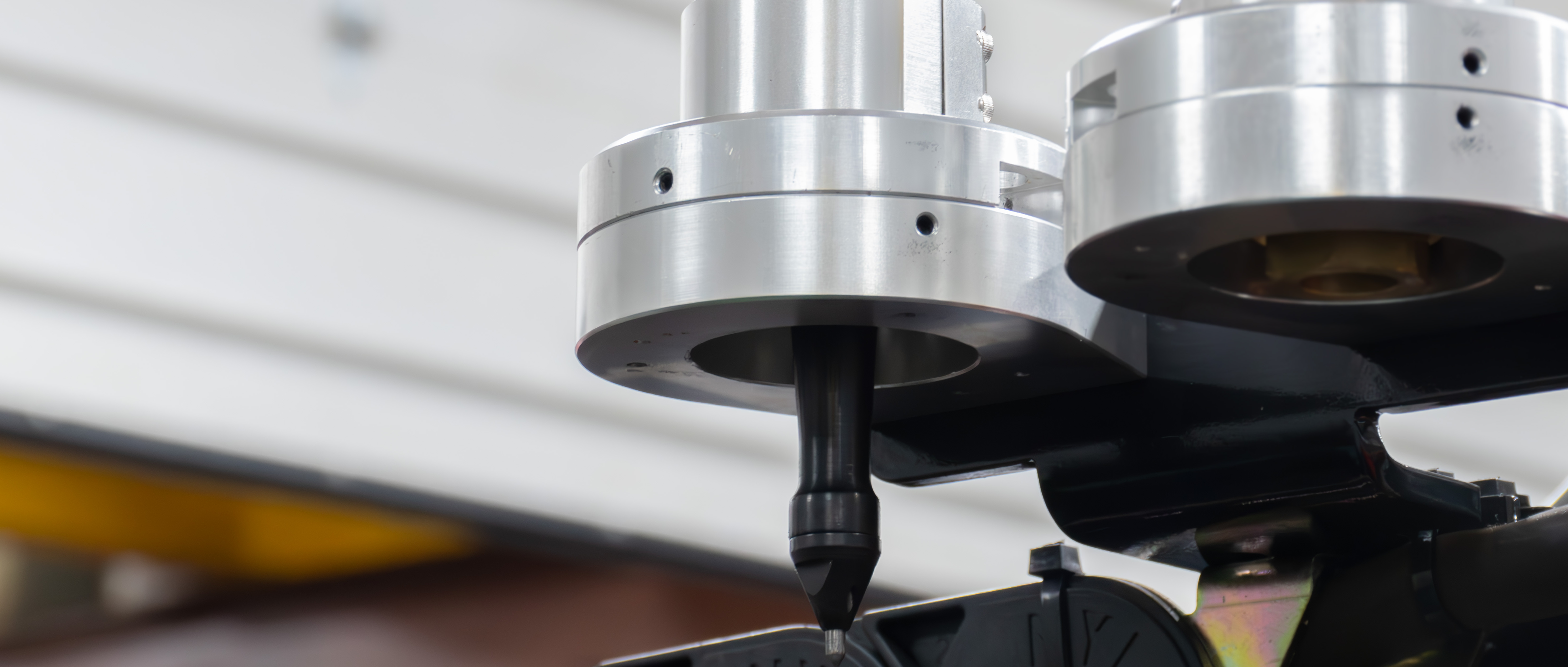

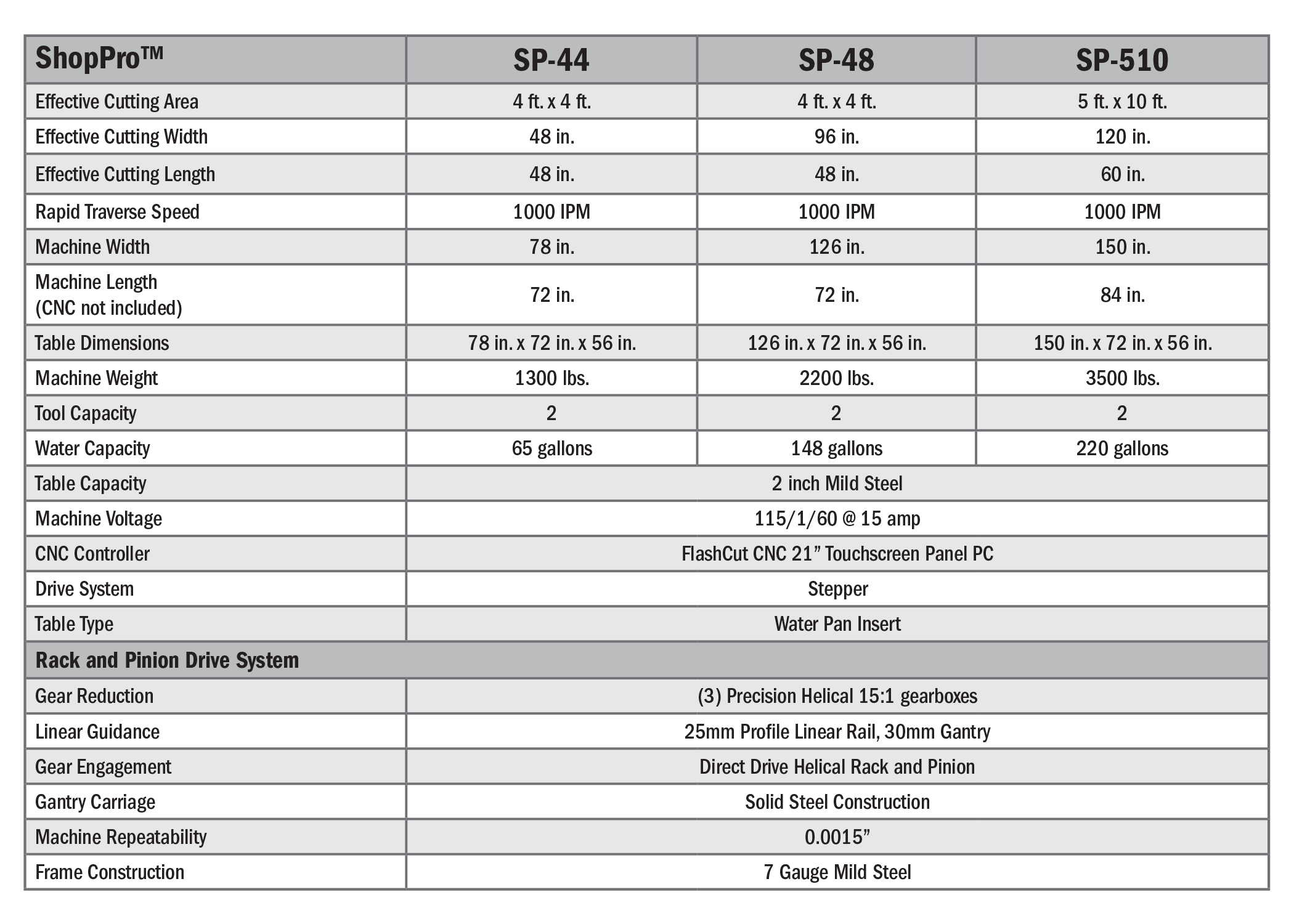

The ShopPro is a high-performance cutting system made in the USA, offering fabricators premium features in a compact package designed to fit small shops. It's ruggedly built, ensuring the same reliability and accuracy found in all Koike Aronson cutting systems.

2 Reviews Hide Reviews Show Reviews Write a Review

-

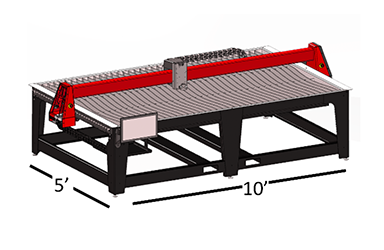

Shop Pro CNC Table

We have had our table for 6 months and the only issue we have had was fixed quickly by their service team within the hour remotely. This thing runs 6 days a week every day in our shop.

-

Shop Pro, should be named Shop Beast

This table puts our old one to shame, it is built like a real machine should be. Its very heavy because its made from thick steel. It will last for many years