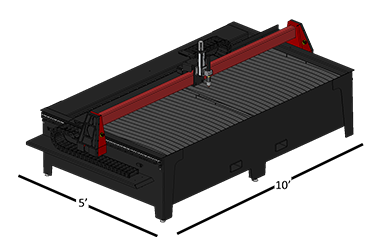

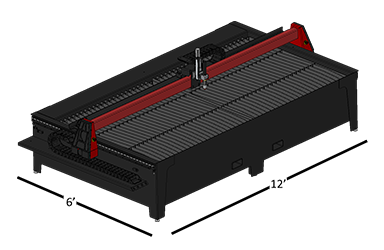

ShopProXHD™ — Everything You Love, Taken Further:

The ShopProXHD™ keeps everything fabricators love about the ShopPro™ platform and pushes it to the next level. With increasedplasma capabilities paired with a deeper cutting table for longer time in between clean outs (three times more slag capacity than shallow table designs), the ShopPro XHD™ delivers precision, endurance, and the same rugged reliability ShopPro™ is known for.