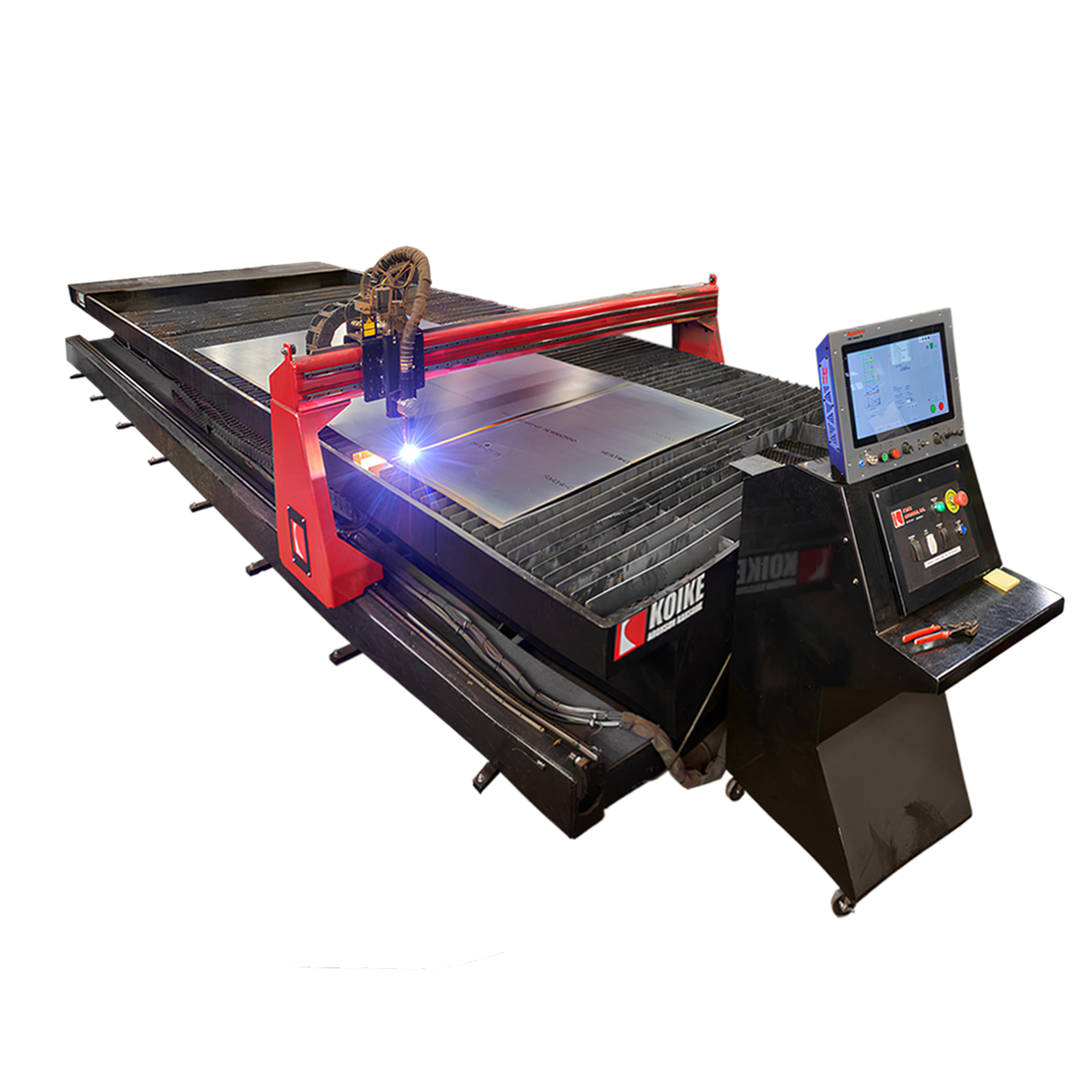

The SuperGraph cutting system stands as a powerful solution, elevating your shop's productivity and consistency, potentially reducing material waste by up to 30%. Its remarkable traverse speed of up to 1000 inches per minute empowers you to maximize production without compromising valuable floor space. The SuperGraph's differentiating factor lies in its compact design, enabling effortless relocation and setup at various locations. As a testament to Koike's unwavering commitment to its universal quality standard, it embodies a high-powered, compact CNC plasma cutting machine.

Features and Standard Equipment:

- Hypertherm® Edge Connect CNC Shape Cutting Motion Controller

- Features 19.5” (4950 mm) Glass Touchscreen (SATA Hard Drive).

- Remote Assistance (when connected to internet).

- Hypertherm’s® plasma Auto-Gas support.

- Simple shape library.

- DXF Direct Input.

- Simple Shape Nesting.

- CutPro Wizard for Beginners.

- Unitized Zoned Downdraft Table Design with CNC Controlled Pneumatic Damper Control for Zone Operation:

- Capable of accommodating up to 1-1/4" plate.

- Features removable slat frame assembly and/or individual slat removal.

- Tuck Rail Design:

- Shields linear bearings, cable carrier, cables, and hoses from harsh environments.

- Optional Removable Slag Pans Available.

PLASMA SYSTEM & OPTIONS:

Hypertherm® HyPerformance/HyDefinition Plasma Systems:

- HyPerformance Plasma cuts fine-feature parts with superior quality and consistency while eliminating cost of secondary operations.

- The quick disconnect torch makes changing consumables fast and easy.

- Long consumable life, dross free edges, minimum angularity and high system reliability maximize productive "arc-on-time".

- HyPerformance Plasma combines fast cutting speeds, rapid process cycling,quick changeovers and high reliability to maximize productivity.

- 130 amp to 800 amp systems are available to meet your production demands.

Hypertherm® Conventional LongLife Air and Oxygen Plasma Systems:

- Heavy-Duty production tools with cost reducing LongLife technology for dramatically longer consumable life and much lower operating costs.

- The quick disconnect torch makes changing consumables fast and easy.

- Impressive cut speeds, consistent cut quality and exceptional consumable life gives this plasma system a reliable performance across a wide range of industrial applications.

Conventional Plasma Systems:

- Hypertherm® powermax65 SYNC®:

- Production Pierce 1/2” Mild Steel

- Hypertherm® powermax85 SYNC®:

- Production Pierce 5/8” Mild Steel

- Hypertherm® powermax105 SYNC®:

- Production Pierce 3/4” Mild Steel

- Hypertherm® powermax125 SYNC®:

- Production Pierce 1” Mild Steel

- Hypertherm® MAXPRO200:

- Production Pierce 1” Mild Steel (Liquid Cooled Torch)

- Hypertherm® XPR300 with Optional Gas Console Boxes:

- Standard Core™console: Production Pierce 1.75 inch Mild Steel; 1.25 inch Stainless Steel

- Vented Water Injection: Production Pierce 2 inch Mild Steel; 1.5 inch Stainless Steel

- OptiMix console: Product Pierce 2 inch Mild Steel; 1.5 inch Stainless Steel

- True Hole™ Ready:

- TrueHole™ Technology founded by Hypertherm® produces a significantly better hole quality than what has been previously possible before using plasma.

- This technology was developed for mild steel from gauge to 1" (25 mm) and has been optimized from a 1:1 to a 2:1 diameter to thickness ratio.

- Hypertherm® ArcGlide Torch Height Control:

- 600 IPM Lifter Speed,

- 9.4” (240 mm) Lifter Travel.

- Initial Height Positioning.

- Corner AVC disable (prevents torch diving during corners).

- Extends consumable life by using Arc voltage sampling with automatic consumable wear adjustment.

- Manual Plasma Bevel Station:

- Bevel in the rail axis only.

- Non-contour mechanical adjustment from +/- 0 - 45°.

- Magnetic Torch Collision Detection:

- Integrated laser pointer with preset offsets.

- Fume Extraction Unit:

- Ledge-less Construction:

Eliminates dust build-up and accommodates wash down environments. - Compact Design:

Minimizes floor space. - Powerful Performance:

Proprietary ExtraLife™ Filter Cleaning System provides 30% more cleaning energy. - Cost Savings:

Fewer filter change outs, reduced filter disposal costs, less energy usage. - Reliability:

Exceptional results for over 20 years and counting.

- Ledge-less Construction:

- CNC Air Conditioning Unit:

- Provides additional cooling - required for machines operating in temps above 120°F (49°C).

- Consists of 1024BTU 115vac industrial tool grade air conditioner and CNC enclosure for external cooling of CNC cabinet.