Shop Categories

-

MRD Turning Rolls

Our cost-effective model combines a reliable single-wheel drive with a stable centerline for consistent performance.

-

Aronson Turning Rolls

A legacy brand, Aronson delivers controlled rotation of cylindrical workpieces through powered and idler rollers.

-

Positioning Equipment

We specialize in providing controlled rotation of cylindrical workpieces using powered and idler rollers.

-

Specialty Rolls

Discover special, purpose-built systems designed to enhance precision, protect materials, and boost shop efficiency.

-

Koike Aronson, Inc

Powered Fit-Up Rolls | Powered Large Vessel Stability from 30 to 1,200 Tons.

Koike Aronson’s TR Series Powered Fit-Up Rolls provide a simple and cost-effective solution for fitting up long vessels with multiple sections. Each wheel is individually powered, allowing for precise vertical and lateral adjustments under load to...Learn More -

Koike Aronson, Inc

A-AAA Ransome Series Turning Rolls

The A-AAA Ransome Rolls are expertly engineered for optimal performance in positioning long cylindrical workpieces. These turning rolls are perfectly suited for tanks, pressure vessels, and pipes, specially designed to accommodate a variety of industrial...Learn More -

Koike Aronson, Inc

B-E Ransome Series Turning Rolls

The B-E Ransome Turning Rolls are meticulously engineered and constructed to facilitate the most effective positioning of long cylindrical workpieces. These turning rolls are ideal for handling tanks, pressure vessels, and large pipes, especially...Learn More -

Koike Aronson, Inc

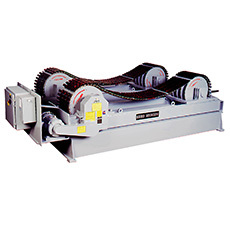

TRAC-TRED | Patented Vessel Rotation System Rated up to 24,000 lbs with Customizable Padding Options

The Trac-Tred Turning rolls provide a solution for safely turning thin walled or precious surfaced cylindrical pieces without marring, wrinkling, or indenting the vessel. The patented Trac-Tred system allows for steady, precise rotation of vessels from 4...Learn More -

Koike Aronson, Inc

Outboard Support Stands | Adjustable Supporting Equipment For Welding Positioners Rated up to 10,000 lbs

The PTR Outboard Support Stand offers adjustable weight capacities of 1,000, 5,000, and 10,000 lbs., accommodating diameters ranging from 2" to 48". Equipped with 8" polyurethane wheels, this stand's roller assembly is mounted on a screw-adjusted stand,...Learn More -

Koike Aronson, Inc

Micarta | V-Block Alternative Turbine Rotor Turning Roll with Dense Precision Resin Wheels

The Micarta Turbine Rotor Turning Roll ━ the smart and cost-effective alternative to industry standards like V-blocks. Whether it's for sonic inspection or welding repair, these specialty positioners simplify the process with cranes needed only for...Learn More -

Koike Aronson, Inc

Self Aligning | Automatic Pinless Precision Alignment Ideal for Tapered Vessels Rated up to 180 Ton

Unlock maximum precision and efficiency with our Self-Aligning (SA) Turning Rolls – the ultimate solution for effortless workpiece manipulation. By automatically adjusting the wheel centerline when your vessel is in place, these rolls eliminate the...Learn More -

Koike Aronson, Inc

Anti-Drift | Patented Vessel Stability With Automatic Adjustment Control Rated up to 1,200 Ton

Introducing the Anti-Drift Roll: the ultimate solution for effortlessly ensuring the stability of your vessel. With its two synchronized "Steerable Wheels" powered by AC servo motors, this cutting-edge system dynamically counters any lateral movement...Learn More -

Koike Aronson, Inc

Steel Wheels | High-Capacity Precision Positioning Steel Turning Roll With Overload Prevention

Koike Aronson's Steel Wheel Turning Rolls, a versatile lineup designed for the efficient positioning of long cylindrical workpieces, including storage tanks, pressure vessels, and pipes. These turning rolls can even be adapted for non-cylindrical objects...Learn More -

Koike Aronson, Inc

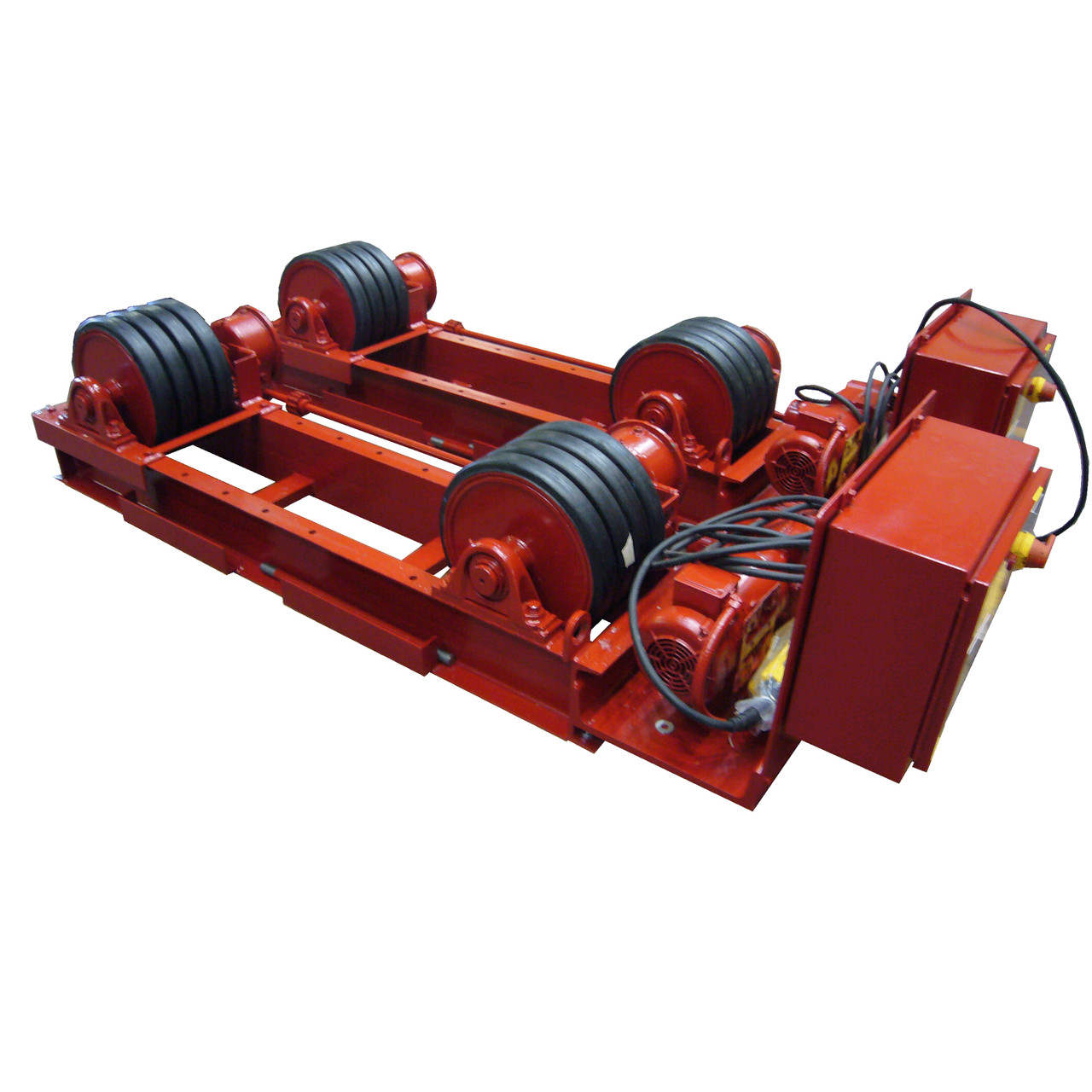

Rubber Wheels | High-Capacity Precision Positioning Rubber Turning Roll With Overload Prevention

Koike Aronson's Rubber Wheel Turning Rolls, a versatile lineup designed for the efficient positioning of long cylindrical workpieces, including storage tanks, pressure vessels, and pipes. These turning rolls can even be adapted for non-cylindrical...Learn More -

Koike Aronson, Inc

Unit Rolls | Modular Spacing Heavy-Duty Vessel Turning Solutions Rated up to 30,000 lbs

The WRU unit frame turning rolls offer a safe and effective solution for turning heavy cylindrical vessels without causing any damage such as marring, wrinkling, or indenting on the workpieces. With capacities spanning from 5,000 to 30,000 lbs, these...Learn More -

Koike Aronson, Inc

Pipe Rolls | Adjustable High-Capacity Light-Weight Turning Rolls Rated up to 6,000 lbs

When it comes to Pipe Rolls at Koike Aronson, versatility and performance are at the center. Our PRD3 and PRI3 rubber-tired Driver and Idler rolls are designed for ease of use and transportability, making them ideal for any work site. Despite their...Learn More

Built for Accessibility, Trusted for Performance

Adjustable rotation is our foundation. Every turning roll we design is engineered to deliver smooth, consistent motion for cylindrical workpieces, ensuring flawless welds and improved operator safety. From compact shop solutions to massive 1,200-ton vessel systems, our turning rolls combine advanced control, heavy-duty construction, and decades of engineering expertise. Whether you’re fabricating pressure vessels, tanks, or turbines, Koike turning rolls keep your workflow efficient, your welds precise, and your downtime minimal.

Contact Koike

Ready to enhance your welding precision and productivity? Contact Koike Aronson, Inc. to find the right turning roll solution for your operation.