Ruggedly built, the Cricket-I provides the same reliability and robust performance found with all Koike machines, offering fabricators a variety of premium features with a small enough footprint to fit into any size shop. The Cricket-I provides a stable and repeatable platform for semi- automatic welding processes and is built with a 150 pound capacity with options.

Features and Standard Equipment:

- Size and Mobility:

- 6’ X 6’ manipulator equipped with manual travel car.

- Weight Capacity:

- Impressive 150lbs load capacity.

- Mast Rotation:

- Manual mast rotation for precise positioning.

- Adjustable Reach:

- Flexible manual reach for enhanced versatility.

- Vertical Lift:

- Powered vertical lift for efficient handling.

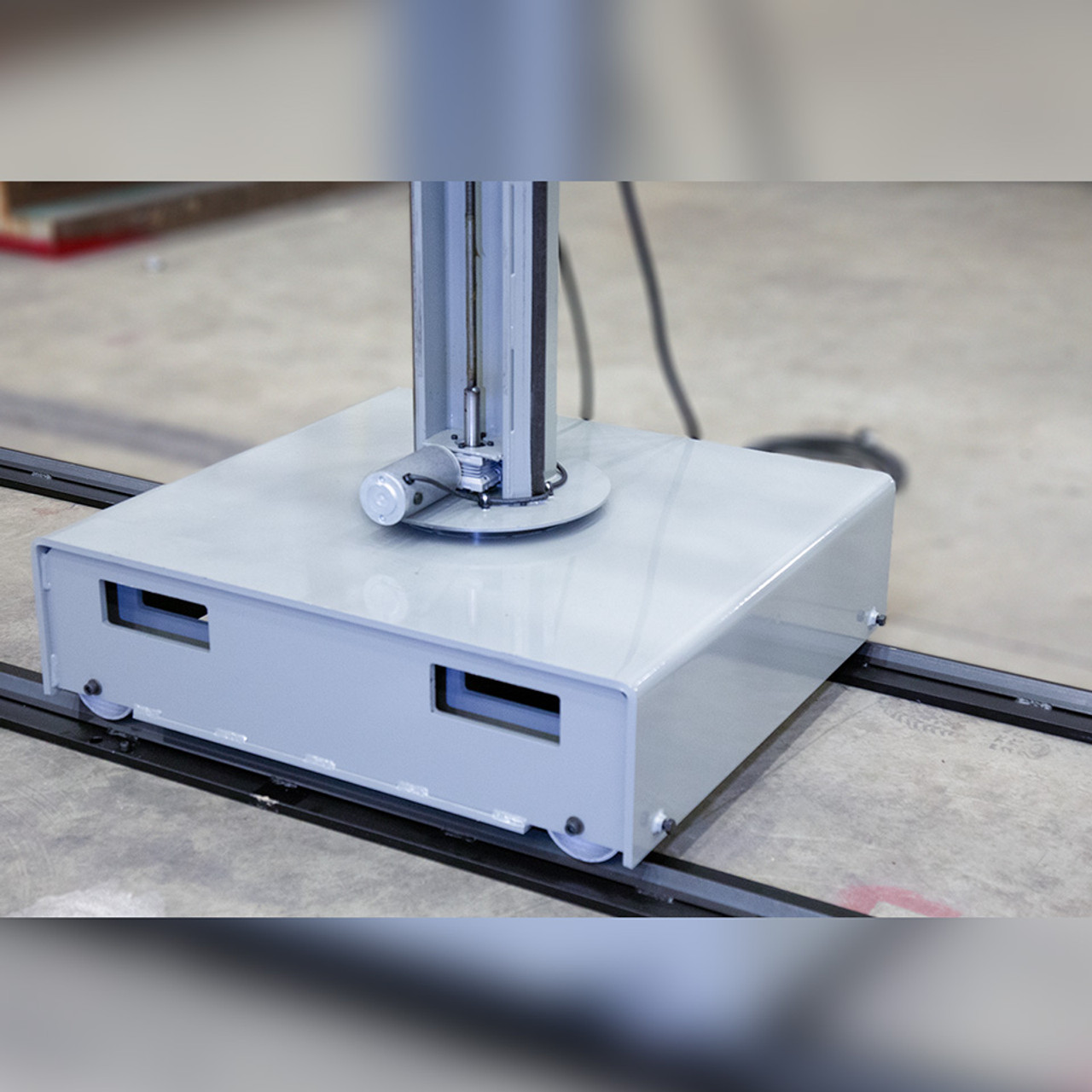

- Mobility Features:

- Convenient fork truck pockets and lifting eye for easy mobility.

Optional Pipe Welding Package Includes:

- Wel-Handy Next

- Programmable WU-3 Weaver and Control

- 3in. x 3in. Manual CRoss Slide

- Mounting Brackets for Pendants and Welding Controls

- Industry-Leading Standard 2-Year Warranty Backed by Lifetime Phone Support.