Shop Categories

-

Chain Lift

Equipped with a chain-driven lifting mechanism, used to precisely position the welding torch.

-

Rack and Pinion Lift

A mechanism consisting of a linear rack and a rotating pinion to lift and move objects vertically.

-

Cricket-I

Our compact, cost-effective manipulator featuring a robust body, powered lift, and optional rail support.

-

Cricket-II

Our medium-duty, ball screw manipulator featuring a 500 lb load capacity, powered lift, and cross-slide support.

-

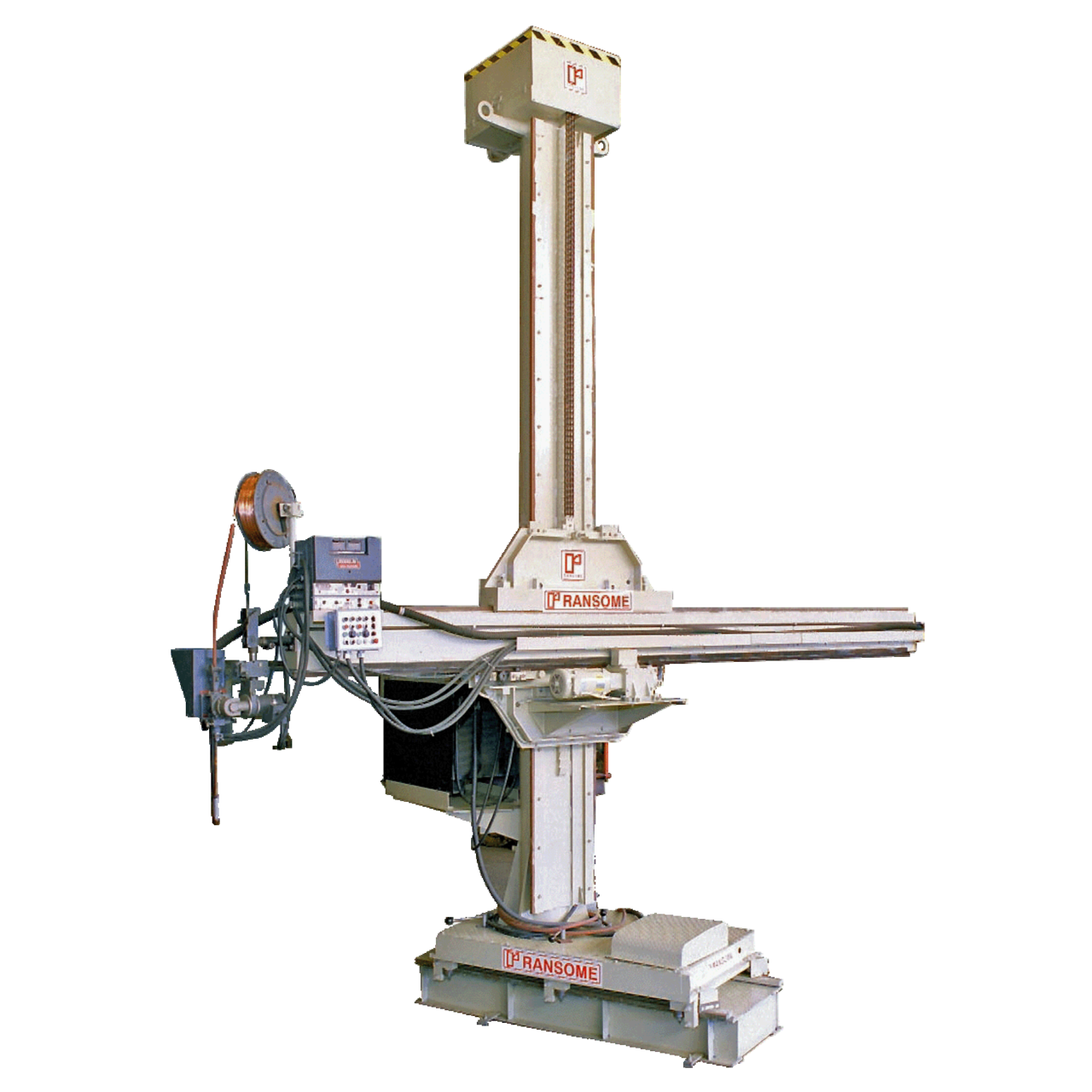

Koike Aronson, Inc

Scarab Series

The Gear-elevated Scarab Manipulator series (Scarab I, II, and III) has been meticulously crafted to prioritize safety and ensure a trouble-free, extended lifespan. All critical mechanisms are securely enclosed, load-carrying gear cases are...Learn More -

Koike Aronson, Inc

Locust Series

The Gear-elevated Locust Manipulator Series (Locust I and II) has been meticulously designed to ensure safety and deliver a trouble-free, extended lifespan. Key mechanisms are securely enclosed, load-bearing gear cases are expertly welded in place, and...Learn More -

Koike Aronson, Inc

Model 1212 | Customizable & High-Capacity Mid-Range Chain Lift Welding Manipulator

The Model 1212, part of Koike Aronson's mid-range chain lift manipulator line, offers exceptional customization options tailored to specific applications, ranging from straightforward straight-line to intricate circumferential welding tasks. These...Learn More -

Koike Aronson, Inc

Model 99 | Customizable & High-Capacity Mid-Range Chain Lift Welding Manipulator

The Model 99, part of Koike Aronson's mid-range chain lift manipulator line, offers exceptional customization options tailored to specific applications, ranging from straightforward straight-line to intricate circumferential welding tasks. These...Learn More -

Koike Aronson, Inc

Model 66 | Customizable & High-Capacity Mid-Range Chain Lift Welding Manipulator

The Model 66, part of Koike Aronson's mid-range chain lift manipulator line, offers exceptional customization options tailored to specific applications, ranging from straightforward straight-line to intricate circumferential welding tasks. These...Learn More -

Koike Aronson, Inc

Cricket-II | Medium-Duty Welding Manipulator Ideal for Subarc, GTAW, & GMAW Applications

Introducing the Cricket-II Manipulator, a versatile welding solution designed to handle a wide range of applications with ease. This medium-duty ball screw manipulator boasts an impressive 500 lbs. load capacity, making it the standout choice...Learn More -

Koike Aronson, Inc

Cricket-I | Compact & Robust Semi-Automatic Welding Manipulator

Ruggedly built, the Cricket-I provides the same reliability and robust performance found with all Koike machines, offering fabricators a variety of premium features with a small enough footprint to fit into any size shop. The Cricket-I provides a...Learn More